Complete instrumentation solution for sterilisation process in a palm oil application

Find out how a range of specialist products from KOBOLD were applied to the sterilisation process at a palm oil mill in order to help improve reliability and ensure accurate measurement of process parameters.

The sterilisation process in palm oil mills

With harvested fresh fruit bunches delivered directly from nearby plantations, palm oil mills manufacture palm oil through a four stage extraction process. Namely: sterilization, stripping, digestion and oil extraction.

During the sterilisation process bunches of palm fruits are placed inside autoclaves and are sterilized using high-pressure steam. This prevents the build-up of fatty acids, helping to loosen and soften the fruits.

Here's an overview of the 'Complete Instrumentation Solution' from KOBOLD that's meeting the needs of the modern Oleo-Chemical industry and in this case helped a palm oil mill's production line run even more efficiently and economically than ever.

Instrumentation solution for sterilisation process

NBK Magnetic Level Gauge

KOBOLD NBK bypass level indicators are used for continuous measurement, display and monitoring of liquid levels and are commonly used for measuring level in storage tanks, agitator vessels, tanks on ships and water tanks.

By installing the NBK level gauge, the palm oil mill could directly measure the levels within the steam drum. Offering a maximum temperature rating of 400°C, the NBK was extensively used in the manufacturer's boiler application.

TWL Temperature Transmitter

Temperature measurement was a basic requirement in the manufacturer's steam management system. KOBOLD provided the TWL temperature transmitter as a perfect solution for their application needs, offering a vast range of temperature sensors available for specific applications.

KOBOLD resistance thermometers comprise a rugged installation fitting made of stainless steel with thread, flange or weld-on connection, a connection head out of aluminium casting and a removable measuring element. The measuring insert can be replaced without emptying the installation, since the customised thermowells remains in the installation and seals the process.

PAS Pressure Transmitter

The KOBOLD PAS Pressure Transmitter is a micro processor-based high performance transmitter, which has a flexible pressure calibration and a flexible output signal.

The PAS series offered pressure measurement with ±0.075 % (of calibrated span) accuracy ensuring that the client continued to receive continuous, accurate readings and monitoring throughout their process.

With a continuous self-diagnostic function and automatic ambient temperature compensation, the reliability of the PAS Pressure Transmitter is unrivalled.

PAD Differential Pressure Transmitter

The KOBOLD differential pressure transmitter is a micro processor-based, high-performance transmitter which has:

- Flexible pressure calibration and output

- Automatic compensation of ambient temperature and process variable

- Configuration of various parameters

- Communication with HART protocol

- ATEX approval

The differential pressure transmitter PAD was used, in conjunction with an orifice plate assembly, in two steam applications. The first application enabled level measurement of the steam drum and the second enabled the flow measurement of steam in the pipelines.

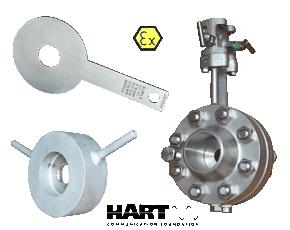

KPL Orifice Plate Assembly

The use of orifice plates continues to be a classical method of steam flow measurement, which is still extensively used in boiler applications. In combination with a differential pressure transmitter, it provides an economical way to measure the steam flow in big pipelines.

DVH Vortex Flow Meter

The KOBOLD Vortex Flow Meter utilises 3 primary sensing elements: a vortex shedding velocity sensor, a RTD temperature sensor and a solid-state pressure transducer to measure the mass flow rate of gases, liquids and steam.

In circumstances where extremely accurate steam flow measurement was required the mill clients installed the DVH vortex flow meter with in-built temperature and pressure sensors. This device ensures on-going correct readinpalm1g of compensated steam mass flow.

In systems that use external process measurements, adequate compensation may not be given for changing rapidly process conditions, between the point of velocity measurement and the point where upstream or downstream pressure and temperature measurements are being made. The DVH multivariable flowmeter measures all of these parameters in a single location, thus delivering a more accurate process measurement.

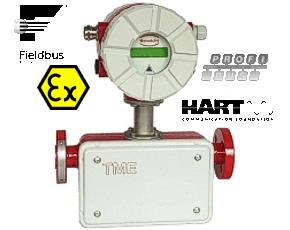

TME/TMU Coriolis Mass Flow Meter

KOBOLD’s highly accurate TME or TMU coriolis mass flow meters were installed for the clarification stage, to measure the liquid before it is transferred to storage tanks. The TME device provides measurement of the flow rate/total flow in mass or volumetric units. At the Storage Tanks Farm, a Coriolis Mass Flow Meter is uses in the truck loading bay to ensure that the amount of transferred CPO is always correct.

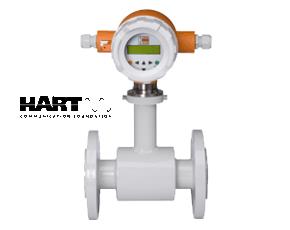

DMH Magnetic Flow Meter

Finally, at the Raw POME treatment facility, where measuring the flow of produced waste water is crucial, the DMH magnetic flow meter was installed. With rated accuracy of ±0.3 %, this device is now extensively used in the water/waste water treatment process.

This information was taken from a KOBOLD application story on Palm Oil production. For moe information about KOBOLD's range of instrumentation, click here.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.