DARPA Robotics Challenge tests the metal of the best robotics engineers in the world

Twenty four global teams of robotics engineers have gone head to head to win the US Department of Defence's DARPA Robotics Challenge. PIF takes a closer look at the challenges they had to overcome to scoop a share of the $3.5m (£2.3m) prize money.

The devastating earthquakes in Nepal earlier this year brought the subject of disaster relief into sharp focus. Getting aid relief to the crumbling infrastructures of third world countries has always posed a problem. But could robots hold the answer for future disaster related operations?

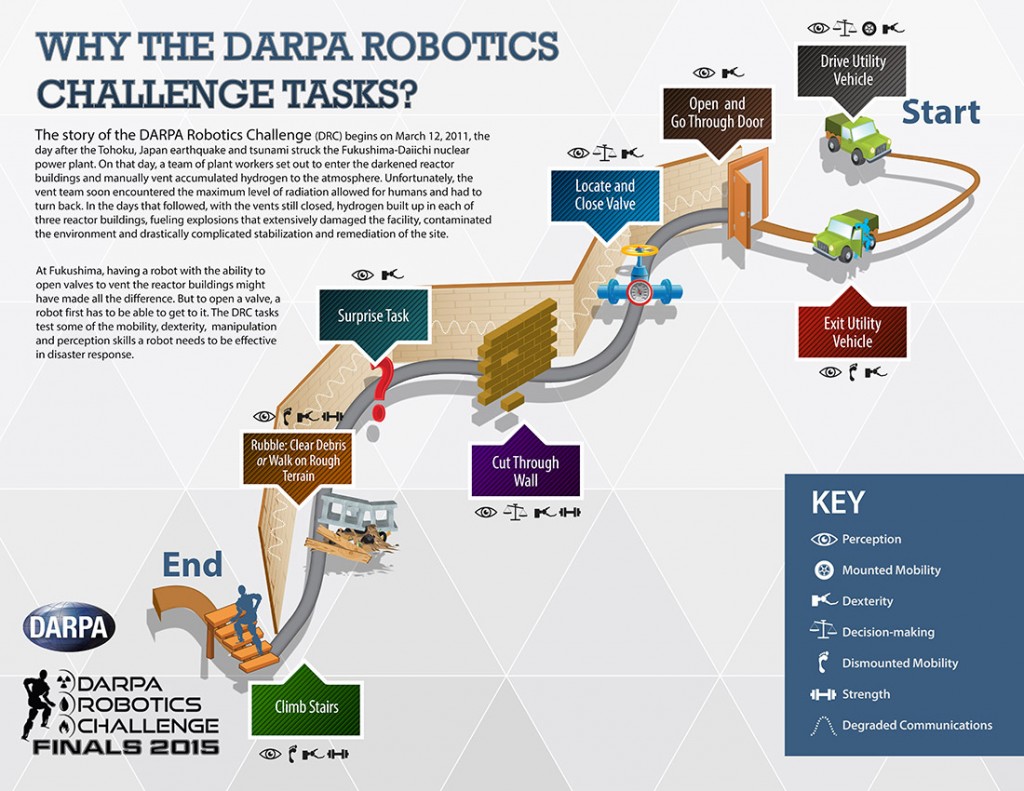

That's the question posed by the DARPA Robotics Challenge (DRC) – a competition of robot systems and software teams vying to develop robots capable of helping humans to respond to natural and man-made disasters.

What is the DARPA Robotics Challenge?

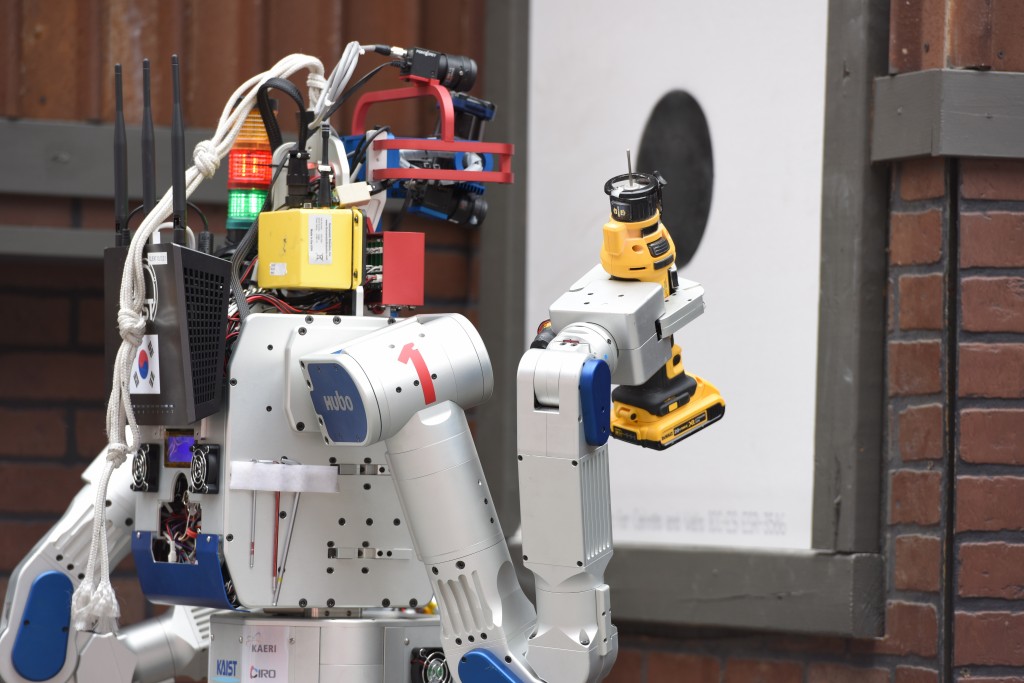

The DRC finals, which took place in Pomona, California from 5-6 June, saw some of the most advanced robotics research and development organizations in the world pitting the wits of their high-tech hardware, software, sensors, and human-machine control interfaces against a series of disaster response focussed challenges.

The eight demanding tasks on the day included driving and getting out of a car; opening and walking through a door; opening a valve; using a drill to cut a hole through a wall; crossing debris-strewn terrain; climbing steps; and a mystery event that was only disclosed on the day. Each team was allowed two attempts to complete the circuit within an hour, scoring a point for each completed task.

Adaptation of robotics technology into disaster response

The finalists – who included specialist teams from the US, Germany, South Korea, Japan and Italy – were seriously tested by the difficult parameters of the final. Speaking to the BBC before the event, DRC Manager, Gill Pratt, said: "We're not allowing any safety belays - the ropes that were used to stop the robots from falling over. If they fall down they have to not break too badly and get up by themselves.

“If they can't get up then the team is forced to take at least a 10 minute penalty and send the robot back to the beginning of the task. We're not allowing power cords anymore - the robot has to keep all the energy on board using batteries. And we used to have a fibre optic cable that connected the robot to the operator, and we modulated the connection's quality to give a little bit of difficulty.”

Ms Pratt added: “The disaster response market for hardware is very small, and so what it typically does is adapt hardware built for some other purpose - the same way a fire truck, for instance, uses engines and wheels built for a truck of a different sort.

What we really need is a growth in the robotics industry for general use, and then the adaptation of that technology into disaster response. What we are trying to do here is just to show what is possible.

We can't help but be reminded of the 1980s movie Short Circuit. Could a robot, not unlike Johnny 5, soon be the first wave of response in disaster situations? Hopefully so, if the DRC teams have anything to do with it. Although DARPA admit that the technology being tested right now is at least 10 years ahead of its time.

For more information visit www.theroboticschallenge.org.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.