Murrplastik multi-tag delivers flawless service for telecoms provider

When a major telecoms provider required a near-impossible cabling label that needed to display up to 60 identifiable parameters at any one time, they only had one manufacturer on speed dial: Murrplastik. In this case study, Tim Bradbury, National Projects Manager, explains how Murrplastik provided their telecoms customer with a flawless service, thanks to their innovative “multi-tag” industrial labelling solution.

The challenge

Back in the beginning of 2018, I got a lead from an ex-colleague about a company who were looking to find some specific labels for the telecoms industry. When I first looked at the project I thought about walking away from it because it wasn’t really our remit and was a little bit out of the ordinary. However, once they told me what sort of volumes were involved, I went away and had a bit of a look.

The remit was that we had to come up with a label that would be specific for a particular requirement in the telecoms industry. This particular label had to incorporate all the information that could ever be needed. In effect, they could have one label that they would use for any type of installation. So it needed to carry all the information but then we needed to figure out a way that they could identify each respective part of the data.

For example, if it was clipped to a certain cable it would need to have certain parts of the information highlighted that they knew which part of the data was mentioned on that cable mount. There were nearly 60 pieces of information that needed to be identified on this label. This label also had other criteria to meet. It had to be suitable for outside use and it had to be guaranteed to stay visible for a minimum of 10 years.

The solution

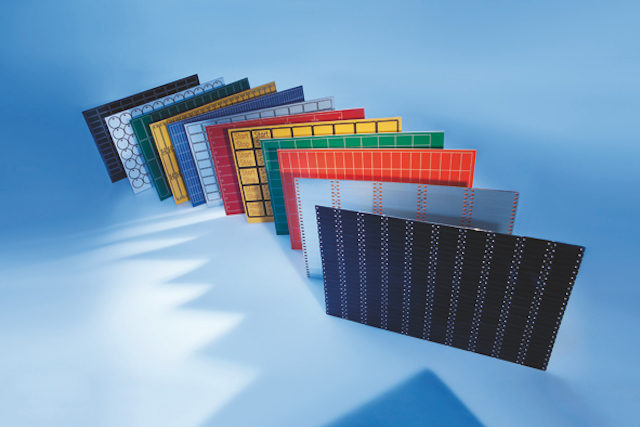

What we did was we came up with a label with our DuoMatt material, which is a two-ply copolymer material. We used an indelible inkjet system to spray-print all of the technical information needed on this label. Then, next to each part of the data, we would laser through the top face of the label a small 1.5mm diameter circle, so it wouldn’t go all the way through, it just broke the top layer, and left a specific point.

We got to the point where we lasered this little dibent through the top layer, exposing the colour underneath. Then there were two options. We could either punch out that circle completely with a tool so that you could see through it. But that gave us a bit of a problem with contrast, depending on what was behind it. We then did some experimenting and found that we could use indelible paint markers with a nib of the same diameter, so that the installer could then really quickly identify which pieces of information they wanted on there.

We also had to do some accelerated UV and wear resistance testing. Then the label had to go through extensive testing with the end user. The client was involved in the design concept as well. There was a previous label in place before we got to look at it but it had nowhere near the amount of information that it now carries. There was an update to all the systems that are now being rolled out. To cope with that, we had to increase the label size very slightly to get all this extra information on.

There was a little bit of a problem with the very first one that we did. We didn’t realise that some of these labels could actually be mounted to a cable smaller than the diameter we’d envisaged. We did get a little bit of feedback that they could occasionally break their back through a zip-tie mount. These labels also have a slot laser cut out for a zip-tie to go through to wrap them around. So we had to make a small modification where we increased the thickness of the materials slightly and re-positioned the position of the zip-tie slots, which resolved the issue.

The result

It has to be “one-label-fits-all”, so it’s actually known as a “multi-tag”. The installer has got a bag full of these things, can zip-tie tie it to whatever cable he’s working on, and then he can mark it afterwards so there’s no damage to the cable. Because he’s using a paint pen to drop the nib into these little lasered circles, it’s a bit like looking at a very early computer jacquard card. It looks a little bit like a small version of one of those.

It’s always a white circle to indicate that that option hasn’t been used and then to get the highest contrast the bit that they are using is marked out in black. It also has a little piece of information along the bottom with the month and the year. The labels, in effect, once we’ve manufactured them, have got a lifespan of three years. The installation life is three years, so once they’ve bought some they don’t need to change those for three years.

They’ll just cut the zip-ties off, strap another one on and re-allocate whatever information needs to go on there. If they’ve made a change at either end of the cable, it’s going into a different piece of equipment or serving a different function, they can just zip-tie on a new label and mark it accordingly. It makes the installation very quick, very robust and the installer doesn’t have to fiddle around trying to find different labels and different identifiers. He knows it’s the one label every time and then just picks out what bits he’s used.

It was passed off at the beginning of 2019 and that particular label is now in full production and has been installed across multiple sites. There have been around 100,000 of these labels installed since then. Murrplastik was given the remit, found the solution, got it past all the technical specifications, and now that’s the accepted method for that particular label and what they wanted to do with it. Best of all, we managed to keep within the remit and the price that the end user was expecting.

For more information about Murrplastik and their industrial labelling systems and services, visit www.murrplastik-labelling.co.uk.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.