MIT researchers pioneer mass production technique for cell-sized robots

Researchers at the Massachusetts Institute of Technology (MIT) have pioneered an innovative new method of mass-producing cell-sized robots called “syncells”, which could be used to search out diseases in our blood stream or monitor conditions within an oil or gas pipeline. Process Industry Forum takes a much closer look at this giant breakthrough for microscopic sensors.

Autoperforation” key to syncell production

The key to making tiny devices in large quantities lies in a method MIT’s team of researchers developed for controlling the natural fracturing process of atomically-thin, brittle materials, directing the fracture lines so that they produce miniscule pockets of a predictable size and shape. Embedded inside these pockets are electronic circuits and materials that can collect, record, and output data.

The novel process, called “autoperforation,” is described in a paper published in the journal Nature Materials, by MIT Professor Michael Strano, postdoc Pingwei Liu, graduate student Albert Liu, and eight others at MIT. The system uses a two-dimensional form of carbon, called graphene, which forms the outer structure of the tiny syncells. One layer of the material is laid down on a surface, then tiny dots of a polymer material, containing the electronics for the devices, are deposited by a sophisticated laboratory version of an inkjet printer. Then, a second layer of graphene is laid on top.

Working with the brittleness of graphene for controlled fabrication

People think of graphene, an ultrathin but extremely strong material, as being “floppy,” but it is actually brittle, Strano explains. But rather than considering that brittleness a problem, the team discovered that it could be used to their advantage.

“We discovered that you can use the brittleness,” says Strano, who is the Carbon P. Dubbs Professor of Chemical Engineering at MIT. “It's counterintuitive. Before this work, if you told me you could fracture a material to control its shape at the nanoscale, I would have been incredulous.”

But the new system does just that. It controls the fracturing process so that rather than generating random shards of material, like the remains of a broken window, it produces pieces of uniform shape and size. “What we discovered is that you can impose a strain field to cause the fracture to be guided, and you can use that for controlled fabrication,” Strano says.

Syncells can be as small as a human red blood cell

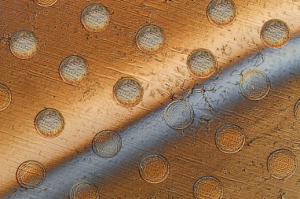

When the top layer of graphene is placed over the array of polymer dots, which form round pillar shapes, the places where the graphene drapes over the round edges of the pillars form lines of high strain in the material. As Albert Liu describes it: “imagine a tablecloth falling slowly down onto the surface of a circular table. One can very easily visualize the developing circular strain toward the table edges, and that’s very much analogous to what happens when a flat sheet of graphene folds around these printed polymer pillars.”

As a result, the fractures are concentrated right along those boundaries, Strano says. “And then something pretty amazing happens: The graphene will completely fracture, but the fracture will be guided around the periphery of the pillar.” The result is a neat, round piece of graphene that looks as if it had been cleanly cut out by a microscopic hole punch.

Ranging in size from that of a human red blood cell, about 10 micrometres across, up to about 10 times that size, these tiny objects “start to look and behave like a living biological cell. In fact, under a microscope, you could probably convince most people that it is a cell,” Strano says.

For more information visit www.mit.edu.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.