How to measure and maintain flow rates

For this latest technical article, PIF spoke to control and instrumentation experts Fluid Controls to gain an insight into how to measure and maintain flow rates effectively. With that in mind, we also take an in-depth look at the functions and advantages of the Kates Flow Rate Controller.

Fluid Controls supplies a range of W.A. Kates flow controllers. Their superior range of automatic flow rate controllers can be successfully applied to a wide variety of liquid and gaseous applications. They're available in sizes from 1/4″ up to 4″ and constructed from a choice of materials, with a wide variety of threaded and flanged connections. These controllers can automatically compensate for changes in supply and discharge pressures, whilst maintaining a constant flow setting.

Kates Flow Rate Controller

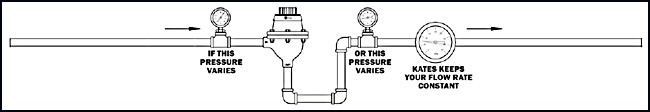

With Kates flow rate controllers, downstream pressure fluctuations are counterbalanced by the internal regulating valve. This maintains the standard cubic feet per minute (SCFM) to within 1-1/2% of the flow setting. Variations in upstream pressure and temperature should also be minimised due to the compressibility of gases and the corresponding changes in density. The ratings of Kates FC Valves are catalogued in gal/min for purposes of standardisation.

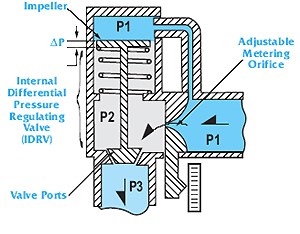

Flow rate through an orifice is proportional to the size of the restriction and the differential pressure across it. By combining an adjustable orifice with an internal regulating valve, the Kates Flow Rate Controller maintains a constant pressure drop across the metering orifice.

How does the Kates Flow Rate Controller function?

The Kates Flow Rate Controller works like this; if supply pressure (P1) increases, the resulting momentary pressure imbalance immediately moves the impeller downward. This action restricts the valve ports thus increasing orifice back pressure (P2), restoring differential pressure and the flow rate to the original settings. The unit will respond equally as well to an upset in outlet pressure (P3).

What are the advantages of the Kates Flow Rate Controller?

The Kates Flow Rate Controller has several significant advantages, including the following:

- Automatically corrects for any changes to the inlet or outlet pressure to maintain the set point flow to +/-1.5% of setting.

- Flow is directly proportional to orifice area.

- “Straight-line" uniform linear scale.

- Accuracy by means of a self-operating single unit.

- No need for 10 - 20 straight runs of pipe diameter upstream or downstream to insure control accuracy.

- No electric, air or hydraulic connections are required.

- Large turndown ratio typical 25 to 1 or better.

- Fast acting.

- On liquid service, moving parts are immersed in the fluid which helps to prohibit hunting or oscillation.

- Simple design and few parts eliminate the many calibration and adjustment checks required of a typical flow rate control system.

For more information about their range of W.A. Kates Flow Rate Controllers, speak to a Fluid Controls adviser today by calling +44 (0) 118 970 2060 or email [email protected].

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.