Bedford Pumps deliver storm pump solutions at UK coastal pumping stations

Bedford Pumps, one of Europe’s leading manufacturers of large submersible and conventional pumps to the water and wastewater industries, have underlined their pumping prowess with the completion of two large-scale installations at major pumping stations on opposite sides of the great British coastline.

They provided specialist storm pump configurations at Merseyside's Altmouth Pumping Station, for the Environment Agency, and Toll House Sewage Pumping Station in Scarborough, for Yorkshire Water. These multi-million pound contracts were the result of significant investments into modernising these crucial facilities. With a view to reducing coastal flooding and minimising the risk of any untreated water entering the sea during periods of heavy rainfall.

Large storm pumps at Altmouth pumping Station

As part of one of Bedford Pumps' largest ever projects, the £4m refurbishment of the pumps and MCC at Altmouth Pumping Station involved replacing four 1800hp diesel driven Storm Pumps that had been operational since the 1970s. With the pumping station responsible for protecting more than 9000 properties, and 20 square miles of premium agricultural land, the stakes were high.

Initial plans at the design stage had mooted replacing the existing Vickers pumps with three Storm Pumps. Each of which would operate at 15m3/s at approximately 4.7m head. However, on Bedford Pumps' recommendation, this was upscaled to four pumps instead. Consequently, the total head was reduced from 4.7m to 4m and saved 600kW on the installed power. The extra pump also reduced the required flow per pump to 11.25m3/s.

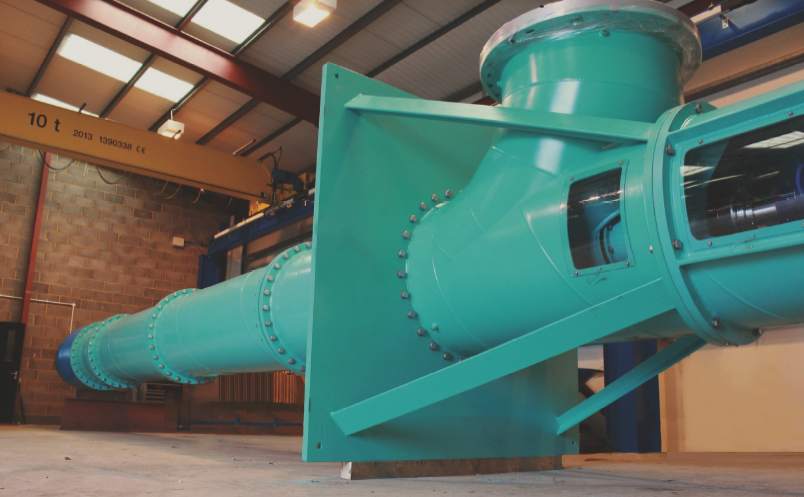

Canister units were favoured, over conventional lineshaft units, which proved more cost effective, better for health and safety conditions, more efficient and freed up valuable floor space. These unique pumps (a revolutionary variant to a standard submersible), designed and manufactured by Bedford Pumps, are driven by 620 kW 3.3kV motors with an integral IP68 planetary gearbox within the unit. The motors could therefore be a 6-pole, rather than a much larger 26-pole motor, negating the need for a direct drive pumpset.

Electric pumps were chosen to replace the previous diesel units to slash their energy consumption and carbon dioxide emissions. That decision also allowed for the station to become fully automated and ensured greater control of the river, resulting in yet more efficiency gains. Bedford Pumps also supplied Dry Weather Flow pumps for routine operations.

Suspended bowl pumps at Toll House Sewage Pumping Station

Scarborough's Toll House Sewage Pumping Station is the first of a trio of Yorkshire Water facilities to be installed with three of Bedford Pumps' suspended bowl pumps for pumping storm water. The £10m refurbishment process has included three large-scale storm transfer pumps to discharge excess storm water from a new 4000 cubic metre storm water storage tank offshore.

Three Mixed-Flow Bowl design Storm Water pumpsets (one duty, one assist and one standby) – featuring steel rising mains, support plates and motor stools – drive mixed-flow impellers, made from bronze to ward off the corrosive effects of the saline, marine surroundings. Each pump is driven by a 12 pole 450kW motor and is equipped to discharge at 3,440 l/s at 10.1m head with a BEP of 86%.

Bedford Pumps was also due to supply four wet well submersible volute pumpsets (for handling raw/screened sewage) at the nearby Scalby Mills Pumping Station, as well as four suspended wet well bowl pumps for storm water protection at Bridlington Wastewater Treatment Works.

For more information visit Bedford Pumps.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.