Fracking – can a ‘buy cheap-buy many’ approach to procurement work in the long term or is the industry compromising safety?

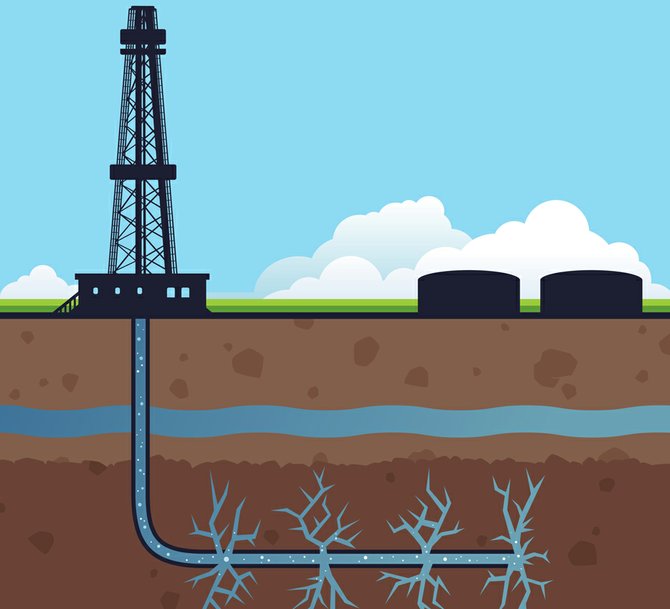

Fracking or hydrofracking is the commonplace name given to the induced hydraulic fracturing of, or the propagation of fractures in the rock beneath our feet. This occurs when pressurised water is forced into well-bore drilled into reservoir rock formations. The process of Fracking should not be confused with that of drilling; it is carried out after the drilling process has taken place.

The objective is to force fluid (mainly water) into the shale rock at high pressure, thereby forcing the shale gas out, whereupon it is collected at the surface and transported by a series of pipes to storage tanks.

There are a variety of valves, instrumentation and pumping equipment used throughout the fracking process. The valves that are deployed in this process will usually always include plug valves, gate valves, and check valves (non-return). On the suction side of the pumping equipment, we will usually see butterfly valves and often swing check valves, safety release valves, solenoid valves, gauges, pressure regulators and assorted flow measuring equipment.

The prevailing investment strategy within the operating companies at the present time is to prefer the less expensive ‘throw-away’ products in favor of those more expensive quality product with greater reliability and a longer life span. One of the key operational challenges to manage is that of valve and pipeline erosion. Operators tend not to overhaul their valves until the valve body is eroded beyond repair, and erosion prevention has in most cases been rejected on the grounds of not being economical.

This ‘buy cheap - buy many’ philosophy exhibited by the fracking industry in general is very similar to that currently deployed within the UK Water Industry, where the preferred procurement strategy is to minimise capital expenditure in favor of operational costs. Within the Water Industry, this strategy may be viewed by many, including the primary stakeholders (ie the public at large) as a flawed approach and one that is perhaps not really in their long-term financial interest. However, the true costs of this approach to investors is often lost or disguised in the financial fog of corporate reporting. One of the reasons that it continues to prevail within the water industry is due to the benign nature of the industry and the process media being transported; there is often no immediate threat to life or employee safety in the event of catastrophic component failure.

However, many readers will be aware that a completely different proposition prevails within the Oil & Gas industry where component failure can often result in catastrophic risk to both employee and public safety. In the wake of Piper Alpha, this industry became very heavily regulated and as a direct consequence, safety standards improved considerably. The industry uses high quality products throughout their entire operation and safety is rarely compromised.

The Fracking industry is as yet relatively new, particularly in the UK and is currently not regulated to the same degree as the Offshore Oil & Gas industry’ -but does it really need to be?

So far, we have not yet suffered a major mishap or yet experienced the consequences of an environmental disaster. However, all the ingredients are there; we have drilling, we have explosive gases being extracted, we have pressurized transportation issues and the storage of a volatile and combustible gas.

Does the current procurement strategy of deploying lower grade or lower reliability engineering components compromise reliability and leave the industry wide open to such a disaster? Should the industry be adopting a more responsible approach to component reliability and engineering safety before society is faced with the occurrence of a major catastrophe OR is this just silly scaremongering?

We would love to hear your thoughts - Please leave your comments below...

If you would like us to cover a particular issue or feature surrounding the area of Fracking, please email us your suggestions by clicking here.

Follow the links to see our infographic on Fracking and our research study into the UK's opinions on Fracking.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.