What does it take to supply a water pump to an Original Equipment Manufacturer?

Supplying components to OE (Original Equipment) manufacturers require a certain quality standard that helps protect the brand and the customer. The water pump is of integral importance to the engine and its associated systems, and for premium manufacturers, a premium water pump is called for. In this article, PIF spoke to David Lewis, plant manager of Mark Water Pumps Limited, to discuss what it takes to supply components to OEMs.

Supplying a Water Pump to OEMs

‘’We currently manufacture a quarter of a million water pumps every year for the OEM, OES and aftermarket channels and have designed, tested and manufactured hundreds of individual designs over the years, so we have plenty of knowledge to reference when producing a new component.

When an OEM sets out to source a manufacturer for its components, the manufacturer is presented with a set of explicit specifications from the OEM. These set specs consist of performance parameters such as flow rates and mechanical efficiency for a given temperature range, plus, accurate package dimensions, hard points and apertures etc.

The OEM will also stipulate, or, collaborate on the type of technology to be included in the component, this typically covers materials to be used for the pump housing and internal parts such as choosing between steel, composite or plastics for impellers, plus, decisions on key subcomponents such as bearings and seals.

Other requirements will be laid out such as the temperature range at which the pump is expected to run reliably; for performance and longevity of the water pump and other engine ancillaries. Quality control during assembly is also very important, all the while making sure practical decisions are being made in order to meet specific cost targets."

Designing a Water Pump

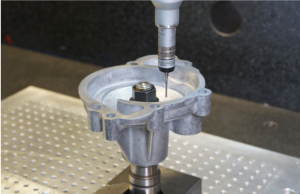

"After the requirements have been set we begin the design stage which involves the use of 3D CAD. Once the design stage has been completed the first samples are machined and assembled, then they are then CMM scanned to ensure that all dimensions have been accurately met. Samples are subsequently thoroughly tested on one of our water pump endurance rigs, which are set to replicate various different life cycle tests, and are also tested on one of our water pump flow rigs to confirm flow rates and pressures. Once the prototypes have passed the testing phase and have been approved by the client then we set to work on manufacturing.

Quality is also a dominant issue. For OE manufactures it goes without saying that it is vitally important that all components operate without issue. And with the water pump being an essential part of the engines cooling system, it not only impacts on efficiency and performance, but just as importantly, reliability and longevity. An OEM needs to be able to rely on its chosen supplier in order to protect its customer satisfaction and brand positioning, both vital in long-term sales allegiance.

All of these stages are carried out in-house at our state-of-the-art factory. By dealing with one supplier from the design stage to rolling out the order, and for every single part of that component, our clients receive the same specification of the pump, every single time.

Everyone at Mark Water Pumps has an OE mentality which greatly helps us to meet the requirements of the manufacturer. We have been designing, testing and manufacturing for OEMs for over thirty years and supply several manufacturers, including prestige brands such as Jaguar Land Rover, Aston Martin and Volvo. We currently manufacture over 250,000 pumps and over 500 different part ranges per year, and have recently invested in the capacity to make more, hold more in our warehouse and deliver them in smaller batches and on very short lead-times. "

OEMs need to work closely with their suppliers to protect their brand and ensure the quality of their products. Buyers of new vehicles will not accept inferior parts and a breakdown will cause damage to the automotive manufacturer's reputation. As the automotive market is so competitive, specifying a water pump from a company such as Mark Water Pumps guarantees quality and a long service life. Ultimately, quality production processes achieves success for both supplier and OE manufacturer. To find out more about original equipment manufacturers, contact Mark Water Pumps today.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.