Valve Terminology: A Basic Understanding of Key Concepts

Process Control is a specialised field which is often accompanied by an unfamiliar language that can be challenging for engineers to use when they are specifying and integrating proportional valves in processes for controlling flow or pressure.

This article provides a basic understanding of control terminology to assist engineers in selecting the correct valve for their application.

Open and closed loop control

Central heating analogy:

Imagine a room with a central heating radiator fitted with a control valve. Open loop control describes how the markings on the valve are used to control room temperature e.g. 30% open provides a room temperature of 25º C. So this is where the valve is set to maintain that temperature.

However, if the room heats up, there is no feedback mechanism to close the valve and maintain the temperature to take account of the change in circumstances. Closed loop control adds this feedback. By adding a room thermostat the temperature in the room would be monitored and a signal provided to close the radiator valve as the required temperature is reached, thus maintaining the temperature at the set level.

It is simple as that!

PID Controller – What is its function?

In the above example, the thermostat acts as a simple controller. Most industrial type controllers provide more sophisticated control and incorporate PID (Proportional, Integral and Derivative) functionality to improve the control accuracy.

The Proportional (P) action will decide how much to change the valve position after it determines the temperature, and therefore the error. In a proportional only controller the valve will be told to open until the room temperature is reached and it will then be told to close. There will often be an offset where the room temperature never actually matches the set point.

The integral (I) action accelerates the change towards the set point and also eliminates any offset. Because the rate of change is greater the temperature will often overshoot the set point and then have to come back down again.

The derivative (D) function notes the temperature is changing, and how fast, it then anticipates further change and alters the rate of change accordingly. This gives a ‘soft’ landing at the desired temperature.

Hysteresis, Deadband and Linearity

All of these factors will affect the accuracy of a valve and its ability to control your process.

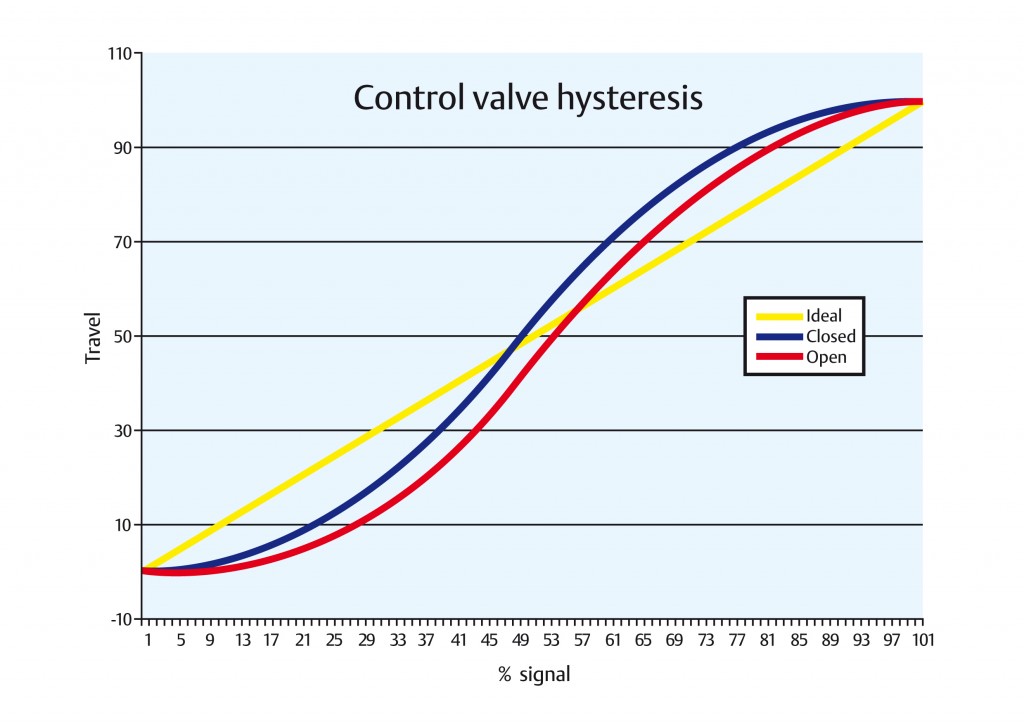

Hysteresis

When related to a valve, hysteresis is the difference between the valve position on the upstroke and its position on the down stroke at any given input signal.

For it to be true hysteresis the valve will be moving at all times. Hysteresis is most often caused by a high degree of static friction within the valve.

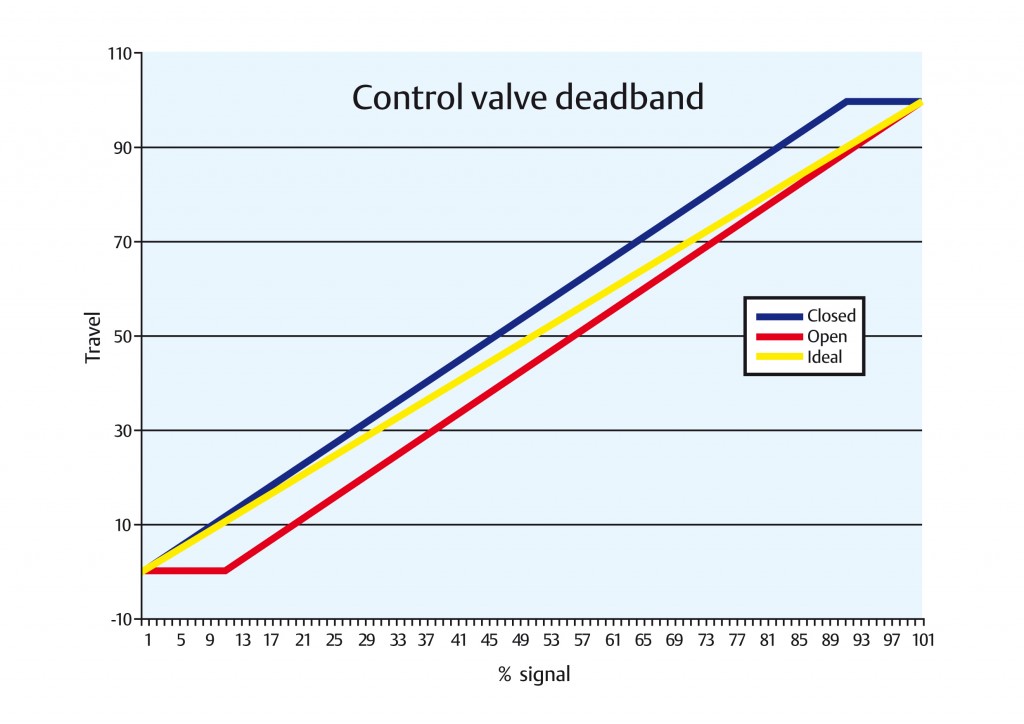

Deadband

Deadband on the other hand is when there is no movement, it generally occurs when the valve changes direction. If you can imagine a linkage with a slot and a pin. As the actuator is moving in one direction, the pin is pressed against the side of the slot, moving the valve. When the actuator changes direction, the pin has to press against the other side of the slot before the valve will change direction. If there is significant play in the slot there will be a period when the valve does not move.

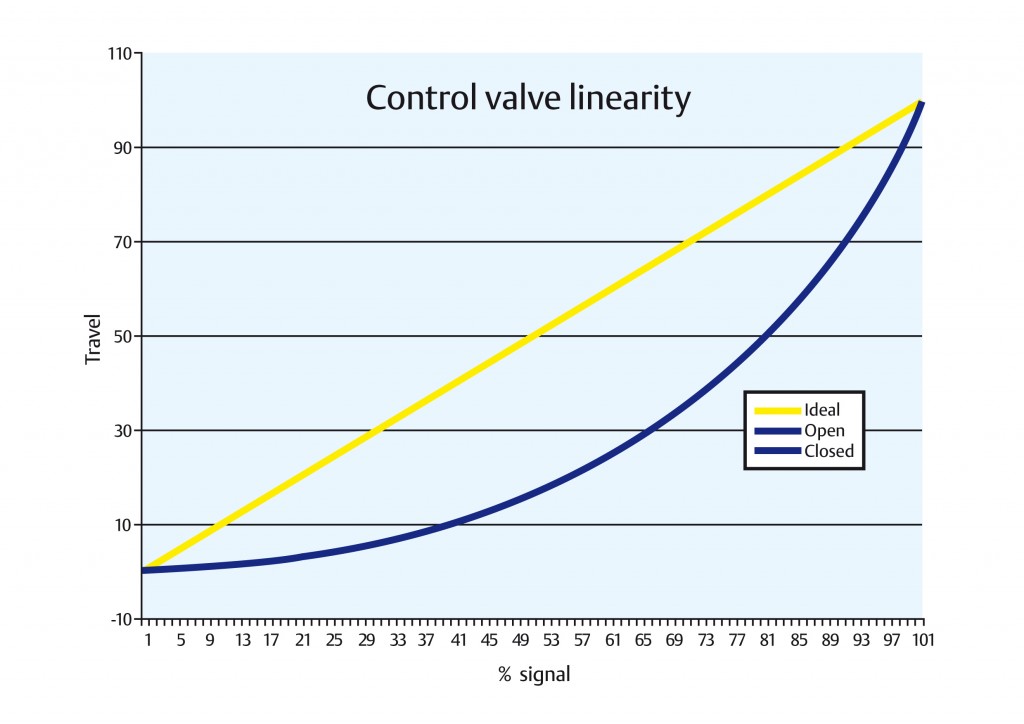

Linearity

The linearity of a valve is related to how close to a straight line the graph of travel vs. signal is;

We hope this tutorial article aids your understanding of complicated valve terminology. If you have any questions, please leave comments below or ask our technical experts a question in the PIF Solution Centre.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.