Val-Matic Test Different Valve Coatings on Combination Air Valves at Wastewater Treatment Plant

Salt Creek Sanitary District Water and Wastewater Treatment Plant (SCSD WWTP) in Illinois provided the perfect application conditions for Val-Matic to test different valve coatings. Val-Matic supply all of their valves with Fusion Bonded Epoxy Coating as standard. The purpose of the investigation was to determine which coating, out of FBE, Teflon and Two-part Epoxy provided the most protection against build-up of harmful deposits in wastewater applications.

Air Valves Coating Experiment

Cast iron combination air valves with 316 stainless steel trim were coated with Teflon, FBE or Two-part Epoxy. For each coating, the underside of the cover, baffle, body interior and float were coated prior to assembly.

After manufacture, they were installed in a valve vault, opposite a submersible pump wet well, downstream from pumps and upstream from check valves. Each valve was installed on a raw sewage main, which ran in parallel in the vault. The valves were subjected to harsh raw sewage pumped directly from the plants mechanical screens.

Results of the Air Valves Coating Experiment

The valves were tested periodically for performance over the 3 years they were installed in the plant. The valves had equal usage over the 3-year period, no back-washing or maintenance was required and there was no reported problems of valve operation.

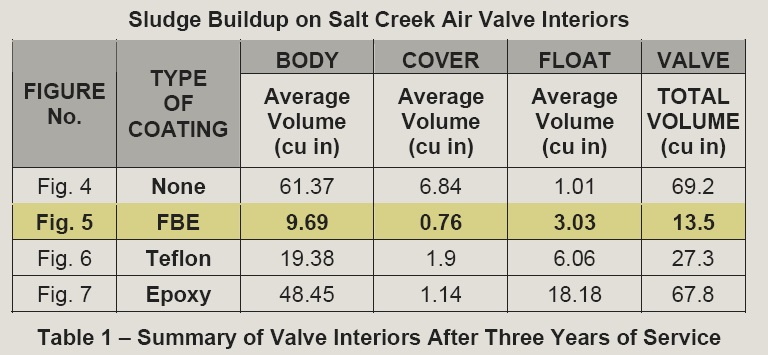

Inspection involved lifting each valve cover and float mechanism from the valve. The results of performance in preventing sludge build-up are presented in the table below.

Comparison of Sludge build-up in Air Valves

The valves with coated interiors were more resistant to build-up of sludge or debris. Of the coatings evaluated, FBE provided the greatest level of protection.

Fusion Bonded Epoxy Coating

Teflon Coating

Two Part Epoxy Coating

Conclusions of the Air valve experiment

The non-clog design and the non-stick FBE coating of the Val-Matic air valves are the perfect solution for severe applications, such as a wastewater treatment plant. The extended valve body prevents solid material from reaching the operating mechanism and the bottom is sloped toward the outlet to prevent clogging.

FBE provides a smooth interior coating, which is able to withstand harsh wastewater applications, thus reducing the frequency of maintenance.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.