SwingFlex Check Valve Application in Wastewater Treatment Plant

Check Valve Clogging in Wastewater Treatment Plant

The Problem

Mount Horeb wastewater treatment plant in Wisconsin USA, on the edge of a residential area was suffering huge problems due to the check valves it was using, especially with one station in particular. Furthermore, this station was in the worst position to have a clog as it was preceding 10,000ft of pipe leading to the plant, which was threatening raw sewage spilling into the adjacent residential area.

A cushion swing check valve at the lift station kept slamming and clogging. These particular check valves were allowing sewage to build up on top of the disc restricting the effectiveness of the valve, causing it to slam. Sewage would build up on the disc pushing the disc further down in to the flow creating headloss, clogging and constant slamming. The cushion swing check valves used had a non-metallic insert for the seal. Every time a piece of plastic, wood or any other solid would tap or chip the cork, the seal would begin to weep.

The wastewater treatment plant processes 600000gpd and therefore could not afford downtime. The constant onsite repair and maintenance of these valves was very costly and time consuming, the engineers it was time for a different solution.

The Solution

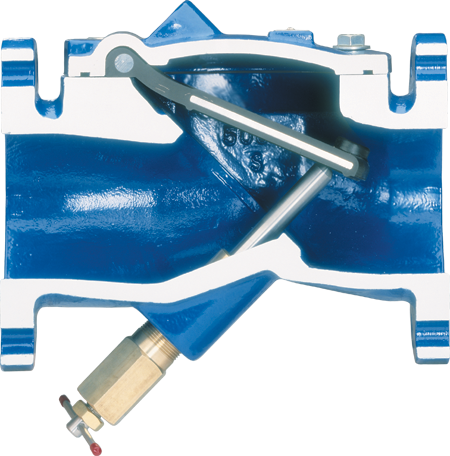

Val-Matic’s SwingFlex Check Valve is specifically designed to overcome the problem they were facing with their cushion swing check valves. Superior features include:

100% Flow Area

The streamlined contour of the Swing-Flex body means there are no restrictions at any point through the valve, and minimal head loss across the valve.

Disc Stabilisation

In the full open position, the disc is stabilised by using body contouring to ease the direction of flow towards the disc assuring long disc life.

Reinforced Disc

The one piece precision moulded disc is steel and nylon reinforced to provide years of trouble free performance.

Non-Clog Design

Unrestricted 100% flow area, smooth streamlined body contouring and the simplicity of one moving part allows passage of large solids, minimising the potential for clogging.

Non-Slam Design

Non-slam is achieved by utilising a “Short Disc Stroke” (35 degree stroke) in conjunction with the unique “Memory Flex action” of the valve’s disc. This reduces potentially destructive water hammer.

After introducing the Val-Matic SwingFlex Check Valve into the one lifting station, the plant decided to replace the remaining cushion swing check valve with the Valmatic Swing Flex Check Valve. For each installation, it took less than 1 hour to remove the previous valve, and install the Valmatic SwingFlex Check Valve and test it for flange tightness.

Have any questions about the SwingFlex Check Valve? Head over to our Solution Centre where you can speak with one of our certified technicians from Val-Matic

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.