What is a Solenoid Valve and how does it work?

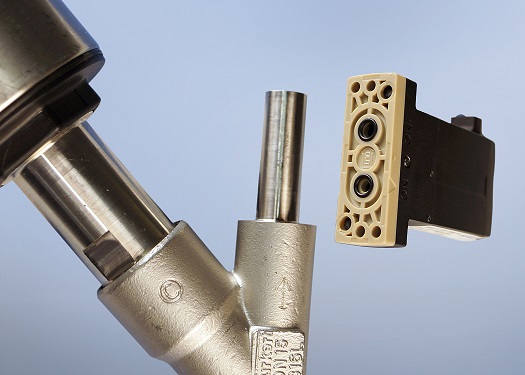

A solenoid valve, otherwise known as an electrically-operated valve is an automatic valve which serves the purpose of removing the need for an engineer to operate a valve manually. Solenoids operate using an electromagnetic solenoid coil to change the state of a valve from open to closed, or vice-versa. If the solenoid valve is 'normally closed', when the coil is energized, the valve gets lifted open by the electromagnetic force produced by the coil.

How to select the correct solenoid valve for your application

For correct and accurate control functioning, solenoid control valves must be configured and selected according to their special purpose. The most important parameters for selecting a solenoid control valve are, on one hand, the Kv value (given in cubic meters per hour) and, on the other hand, the application’s pressure range. The lower the valve’s orifice or the stronger the coil, the higher the pressure the valve can shut-off. On the basis of the calculated Kv value and the pressure range of the planned application, a correspondingly appropriate valve type and its required orifice can be determined.

In what applications would you use a Solenoid Valve or an electrically operated valve?

Any application where a clean (non-viscous) process media, such as very clean liquids/gases/light oils need to be controlled. Simple on/off valves are the most popular as many process lines only need flow or no flow. Solenoid valves can be used in factories/plants where compressed air is not available. They can also be used in place of larger valves such as electrically actuated ball valves, but without taking up anywhere near as much space. Operation is also much quicker than other valve technologies. Other solenoid operated valves use a more advanced technology meaning they can be used to proportionally control flow or pressure depending on a varying input signal. This is where another component further downstream needs a specific pressure or flow to maintain the correct working conditions. Most common input signal used would be a 4-20mA loop signal which most factories will have at their disposal usually controlled by a PLC or similar system. What about options for solenoid valve sealing?

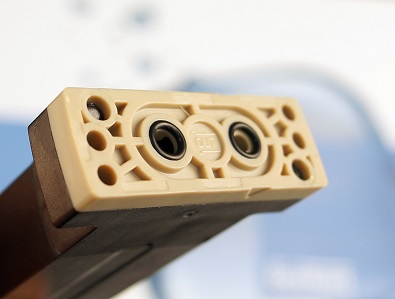

Selecting the correct Solenoid valve seal and materials

There is an extensive range of options for valve sealing and separating membranes. Decision criterion includes the combination of chemical compound, temperature, pressure and cost. These different options and have different benefits and drawbacks. Click here to read more about solenoid valve materials and seals.

There is an extensive range of options for valve sealing and separating membranes. Decision criterion includes the combination of chemical compound, temperature, pressure and cost. These different options and have different benefits and drawbacks. Click here to read more about solenoid valve materials and seals.

What is the difference between Direct-acting solenoid valves and In-direct acting solenoid valves?

- Direct-acting valves require no differential pressure to remain in their rest state and in the NC version, they will only allow flow once energized. These valves are very robust and can be used in a process line for simple isolation purposes of for safety purposes. The can also be used on the outlet to a tank where sometimes pressure can get very low but the valve needs to remain open.

- In-direct acting valves require a pressure differential across the inlet and outlet to allow them to stay in their rest state. For example if a valve was normally open and there was not a large enough pressure differential, the valve could be intermittent and possibly close if inlet pressure dropped too low. These valves should only be used if pressure levels are within the parameters specified in the datasheet and IOM instructions.

For more information about solenoid valves, read this tutorial article on solenoid valves.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.