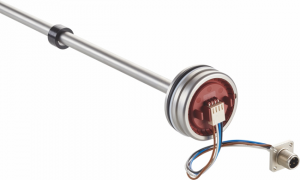

SICK new linear encoder for hydraulic cylinders

Sensor experts, SICK, have launched an innovative new linear encoder for integrated position-measurement in hydraulic cylinders. PIF decided to find out more about how the MAX48 delivers space, cost and maintenance gains for hydraulic mobile machinery.

Space-saving design advantages

The MAX48 is SICK’s first linear absolute encoder to harness the proven advantages of magnetostriction. The German manufacturers have achieved a significantly-longer usable piston stroke length within the tight space of a standard-sized hydraulic cylinder, as well as expanding the amount of operating data that can be monitored in real time and recorded for later analysis.

“The hydraulic cylinder is the workhorse of hydraulic and mechanical machinery and the MAX48 offers important progress in design and operation of machines like agricultural and construction vehicles, cranes and garbage trucks, especially where semi- or fully automated operation is envisaged,” explains Darren Pratt, SICK’s UK product manager for encoders.

“With a shorter head installation depth and damping zone, the MAX48 could deliver up to 10% more operating travel at the popular 300-400mm stroke range. So, hydraulic machinery manufacturers can achieve significant space-saving design advantages compared with cylinders using other measurement devices, as well as providing scope for optimising new machine designs. For example, the space-saving benefit could represent a significantly greater useful reach for a hydraulic arm with several cylinders.

“The MAX48 also delivers unprecedented digital diagnostics capabilities to enable better in-service maintenance and cost-effective operation of machinery and vehicles. The information also provides concrete information for forensic analysis of piston operation to deliver vital data for OEMs to optimise maintenance and service, as well as to investigate cylinder failures in the field.”

Easy to install and fully EMC compliant

The SICK MAX48 absolute linear encoder delivers 0.1mm resolution with between 50 and 2,500mm stroke length to ensure precision control. The 48mm-diameter housing of the MAX48 is compatible with existing cylinder designs prepared for encoder assembly, making it easy to install, and is fully EMC compliant for all mobile machinery types.

It also offers integrated digital diagnostics that give operators, OEMs and cylinder manufacturers insight into the condition, service conditions and life expectancy of the cylinders. Data includes minimum and maximum temperature, supply voltage, hours of operation and total piston travel distance.

The SICK MAX48 features a broad fluid temperature range of -30°C to +95°C with integrated temperature alarm signal and achieves a high level of durability in harsh ambient conditions outside, inside or underground. All popular interface technologies needed for integration into mobile machinery are offered including a selection of analogue outputs, CANopen, SAE J1939 and PWM.

For more information visit www.sick.com.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.