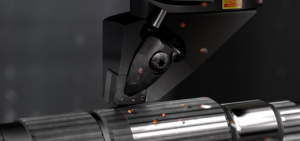

Sandvik Coromant offers Complete Solution for hard-part Turning Operations

With the addition of their two latest products, cutting tool and tooling system specialist Sandvik Coromant now provides a complete hard-part turning solution. CB7125 and CB7135 are optimised for turning steel materials with a hardness of 58-62 HRC, as well as offering longer and more consistent tool life, good levels of surface finish and consistent dimensional tolerances.

In this article, PIF spoke to Sandvik Coromant about why their latest products can help ensure a complete solution for hard-part turning operations.

The Complete hard-part Turning Solution

The CB125 and CB715 grades provide the ability to perform medium-to-heavy interrupted cuts and remove the hardened layer (depth of cut up to 2mm) in case and induction-hardened steel components, typically for the automotive industry.

These grades will work along the existing and complimentary CB7105 and CB7115 grades, which are suitable for continuous or continuous-to-light interrupted cutting operations.

“For everyone working with transmission and other hard-turned components, there is a reason to choose these CBN grades,” explains Torbjörn Ågren, Product Manager-General Turning at Sandvik Coromant. “Not least because adding value in speed capabilities and providing a more secure edge line and consistent tool life means lower cost per component. This is particularly the case when aiming for a one-cut strategy, namely a single cut with larger chip thickness, at high speed.”

CB7125 & CB6135 product specifications

Designed for medium intermittent cutting, CB7125 features a new PVD coating that provides improved wear and fracture resistance for extended tool life. This grade, which contains medium CBN content, is ideal for turning of shaft splines and shafts with chamfered oil holes or pockets. Further applications include the facing of gears, the hard-to-soft turning of crown wheels, and the removal of hardened layers.

The CB7135 grade is pitched at the efficient longitudinal turning of gears and shafts with un-chamfered keyways or pockets, as well as CV joint components such as the inner/outer race and cage. Featuring a high CBN content, the grade offers high fracture resistance and predictable machining results.

Available for T-Max® P, CoroTurn® 107 and CoroTurn® TR tooling systems, the new grades come in both positive and negative basic shapes, with various edge preparations. Cutting data recommendations for CB7125 include a cutting speed of 100-200 m/min (328-656 ft/min) and feed rate of 0.05-0.45 mm/rev (0.002-0.018 in/rev), while for CB7135, a cutting speed of 80-160 m/min (262-525 ft/min) and feed rate of 0.05-0.4 mm/rev (0.002-0.016 in/rev) should be achievable depending on the specific application.

If you are interested in a complete hard-part turning solution, contact Sandvik Coromant today.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.