Patented Flowmeter with SAW Technology for accurate flow measurement in hygienic applications

Bürkert have released an extremely innovative flowmeter perfectly suited to measuring flow in hygienic and challenging applications. The FLOWave flowmeter utilises SAW Technology, meaning accurate and reliable flow measurement can be carried out without sensor elements contacting or restricting the flow of the liquid.

What is SAW Technology?

SAW Technology stands for Surface Acoustic Wave Technology and is uniquely being utilised by Bürkert in their latest flow metering innovation; FLOWave. The main principle of this flowmeter is based on wave propagation forms similar to seismic waves, which start from an initial point of excitation and spread along the surface of a solid material.

FLOWave uses at least four interdigital transducers which are located on the outside of the measuring tube and therefore have no direct contact with the liquid. Each transducer can act as a transmitter or a receiver.

How does SAW Technology work in Flow Metering?

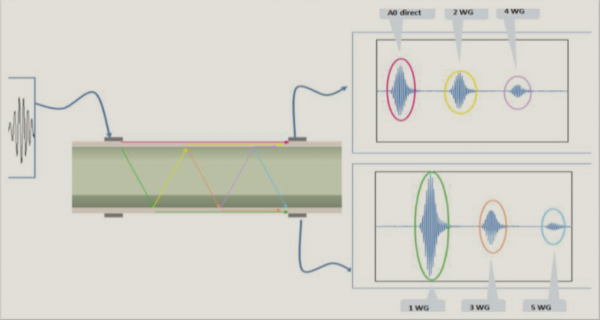

Figure 1. Shows one transducer emitting the wave, part of which travels directly to the first receiver, part of the same signal is transmitted through the liquid to the opposite side of the tube, where it splits again, with a proportion of the signal going to the second receiver and the remainder travelling through the liquid where the process repeats itself. Thus, a single excitation leads to a sequence of signals being received by two other transducers.

The absolute time for the wave to travel from the transmitter to the receiver depends mainly on the tube diameter and the type of liquid. The difference between the time of propagation in the forward and backward direction is proportional to the flow. The analysis of all the signals and comparisons based on different criteria such as amplitude, frequency and runtimes, allows evaluation of the quality of the measurement, the existence of gas bubbles or solids as well as the kind of liquid.

Benefits of the FLOWave Flowmeter

- The primary benefit of this technology is that none of the components come into contact with the liquid and there are no flow restrictions inside the measuring tube.

- The internal surface of the tube can be manufactured to the same surface finish as the rest of the pipeline, meaning that in terms of hygiene, cleaning and flow conditions, there is no difference to any other piece of straight pipe.

- The technology yields extremely accurate and reliable flow and temperature measurement data. In the future, the device will use density measurement to determine mass flow rate.

- The principles behind this design enable the flowmeter to work with a stagnant liquid and so reliable flow figures are available even for the smallest flow volumes.

- The technology also enables it to recognise quick flow changes reliably, which makes it suitable for fast filling processes.

- FLOWave overcomes many of the problems associated with other flowmeters technologies, such as poor accuracy due to vibration, magnetic and electrical issues and poor conductivity of the liquid.

- SAW technology also has the ability to distinguish between laminar and turbulent flows, a feature that will available later.

Not only does this revolutionary design come in a compact and simple design, but this flowmeter can also be installed in applications in any orientation without affecting performance. The initial design, Type 8098, will comprise an all stainless steel body in four sizes, DN15, DN25, DN40 & DN50, fitted with a clamp connection to meet hygienic standards.

This is just the beginning of the FLOWave story, with so many suitable applications and so many advantages, it is predicted the range will grow to provide additional solutions for a much wider audience, enabling more processes and industry sectors to benefit from SAW flow measurement technology.

FLOWave is expected to be commercially available for high purity water measurement applications during 2015. Several units are also currently undergoing data collection duties for calibration in a number of popular food, beverage, water processing and pharmaceutical applications.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.