Hygiene standards in the food and beverage industry

Over the last few years, health and safety standards in the food industry have become increasingly strict. Adhering to these standards is extremely important and failure to do so can result in negative consequences. In order to effectively meet the requirements, the control and measurement of machinery and facilities is important. Murrelektronik provide FDA compliant and ECOLAB approved products, which feature a hygienic machine design, making them ideal for use in food and beverage applications.

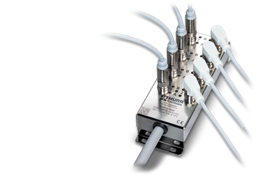

I/O Systems with a hygienic machine design

In order to consistently meet health and safety requirements, all food processing facilities have to feature a hygienic design. Murrelektronik provides hygienic electronic systems and components, suitable for use in food and beverage applications, from start to finish. Here are just a few of the potential products you can use to ensure your machinery meets the health and safety standards.

I/O Systems

With a wide variety of I/O systems, Murrelektronik can specify the exact product to meet your industry and application requirements. Our I/O systems connect the actuators and sensors in a system to the control, with a protection class of IP20 for control cabinets and IP67 for direct installation. Our I/O systems feature a hygienic machine design and are manufactured using robust materials, including stainless steel. Our range of systems include:

Cube 20

Cube 20 is a centralised IP20 I/O station, which features modular function modules. Cube20 can be directly connected to our Cube67 module and, with a high signal installation of 32 channels in one module, wiring efforts are significantly reduced.

Cube 67

Cube 67 is an award winning modular fieldbus system. This I/O modular component is customisable, to meet the specific requirements of an installation solution. With single cable technology, multi-function modules and flexible installation methods, Cube67 transfers both power and data from a single bus node.

Murrelektronik systems with a hygienic machine design

Distribution Boxes

MVP12 Steel Distribution Box

Components in the Food and Beverage industry must feature a hygienic machine design, which is why Murrelektronik’s MVP12 steel distribution box is perfect for the job. This stainless steel distribution box also reduces the need for large amounts of cables, replacing the usual eight sensor cables with just one homerun cable. The MVP12 distribution box can go a long way in assisting the hygienic design of a food processing facility, helping machine builders to comply with DIN EN 1672-2 / DIN EN ISO 14159 standards, and

can withstand continuous high pressures.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.