How do pressure sensors work and how to choose the right specification

Understanding how a pressure sensor works and what questions you need to ask in order to accurately achieve pressure sensor specification for your application is important. In this article, leading sensor and instrumentation technology specialists, Baumer, provides a guide on what types of pressure sensor are available and what applications they are best suited to.

Where pressure is transmitted, pressure sensors can provide reliable and precise solutions. These are customisable in line with the application which is why accurate pressure sensor specification is important. Meaning that it pays to understand the installation conditions, application requirements, and media properties.

Types of pressure sensor

To understand the types of pressure sensor are available, first, you need to understand the difference between the four pressure types.

Types of pressure

- Absolute Pressure – Absolute pressure is definable by the measurement of pressure with respect to vacuum. It is important, therefore, to use a leak-proof sensor without relative compensation.

- Relative Pressure – When you measure relative pressure, you do so in respect to atmospheric pressure. To do this, you need a sensor with relative compensation.

- Compound Pressure – Where gauge or differential pressure from negative to positive values is under scrutiny

- Differential pressure – The measuring of the difference between two different pressures.

Pressure sensor specification is important to ensure you have the correct technology to measure and monitor the above where they are relevant in your application. Some examples of the types of pressure sensor technology available include:

Types of pressure sensor

- Piezoresistive sensor – Known for high-accuracy pressure measurement capability, offering long-term stability. High durability enables use in potentially explosive areas (ATEX) and also to measure all types of pressure.

- Metal thin-film – Can measure even extremely high pressures under high shock and vibration loads. As a rule, metal thin-film sensors measure relative pressure.

- Ceramic, hybrid – This is a well-suited relative and absolute pressure measurement.

- Ceramic, monolithic - Principally, this can only perform relative pressure measurement.

What you need to know for pressure sensor specification

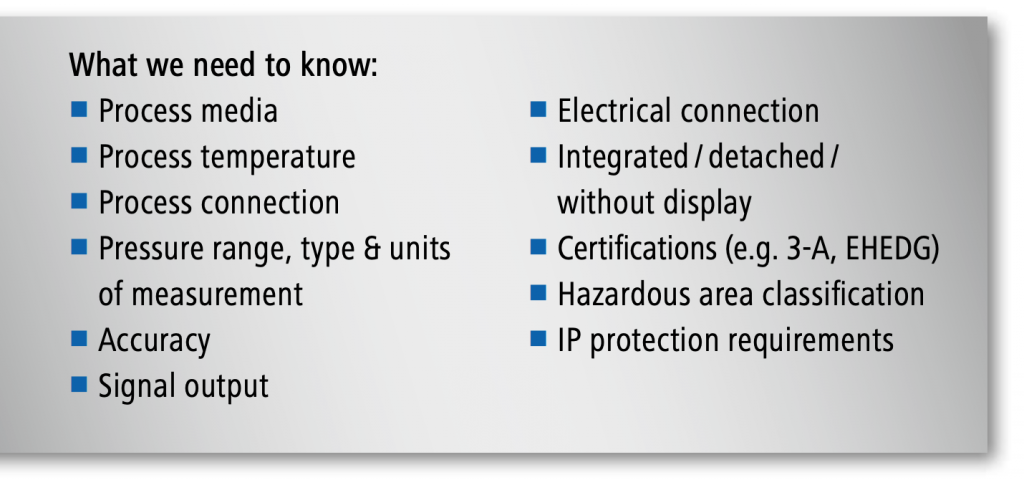

It is important to understand the requirements of your application before deciding on what types of pressure sensor to use. The image below summarises some of the most important things to understand:

Understanding the above and pressure sensor specification altogether will help you to make better choices for your applications. Some of the typical applications where a pressure sensor provides value include process measurement and control technology, leakage detection for applications that use liquids where system pressure requires monitoring, pressure control in pump regulation, and vacuum control in de-aerators.

Visit the Baumer website to learn more about pressure sensor technology and view their product portfolio.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.