Hobbs Valve Innovative Triple Offset Butterfly Valves

Hobbs Valve are industry leaders in the design and manufacture of Triple Offset Butterfly Valves. Hobbs are at the forefront of innovation, producing their patented high performance Triple Offset Butterfly Valves for industries across the globe. Hobbs have patented a range of TVT (Tomorrows Valve Today) metal seated valves that have ground breaking design to provide optimum performance and maximum resistance in high intensity applications.

What are the advantages of Triple Offset Technology?

- Less cost

- Less weight

- Less space

- Zero friction

- Zero leakage

How Does Triple Offset Technology Work?

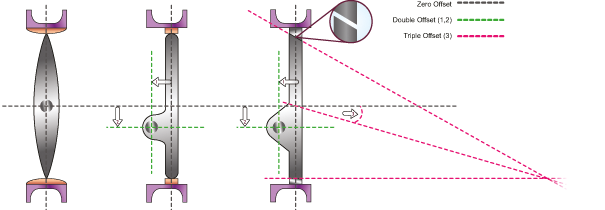

There are three separate “offsets” designed in to the triple-offset butterfly valve. Two of the offsets apply to the location of the shaft in respect to the centreline of the bore and the centreline of the disc / seat sealing surfaces. The third is the design in the axis of the seat cone angle that is inclined from the centreline of the valve bore minimising rubbing of the seat/seal contact surfaces during operation and to preserve sealing integrity over the cycle life of the valve. This wide angle seat also eliminates wedging or binding of the disc. This design overcomes the problem of deformation and friction.

Features & Benefits of Hobbs’ Triple Offset Butterfly Valves:

- Innovative design: The ‘cam action’ and ‘right angled conical sealing design ensures that the metal sealing components are never in contact until its final degree of closing, resulting in repeatable sealing and a vastly extended valve life.

- Triple Offset design: Metal to metal seating ensures bubble tight closure of the valve, resulting in zero-leakage performance.

- No Keyways or Pins into shaft of Valve: A square shaft along the full length of the drive chain eliminates the problems of a weaker shaft, the problem of shearing and allows a lower torque actuator to be used to automate the valve

- Replaceable disc face: The innovative design of the shaft and disc assembly allows the disc to be easily replaced without effecting any other components – reduces maintenance costs and downtime.

- Friction free stroking: The geometric design of sealing components provides friction-free stroking throughout the valve – extends valve life, ensures no over-travel of the disc and allows for a lower torque-range actuator to be fitted.

- Low fugitive emissions: Quarter-turn technology reduces emissions making this Valve more environmentally friendly.

- No cavities between sealing components: Eliminating the ingress of particles meaning no clogging, low maintenance requirements and longer valve life.

Want to know more about the Triple Offset Butterfly Valve? We've got more articles highlighting application problems, valve comparisons as well as going into more detail around the innovative features.

Head over to the 'Solution Centre' and put your questions to one of Hobbs Valve's certified experts.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.