Easy & accurate in-process instrument calibration with electrical resistance thermometer

Temperature Instrument calibration has become quicker and easier than ever with Labom’s In-Process Calibration method. For applications where stringent accuracy levels are not always required or for when engineer’s are looking to lengthen the time period between complete instrument calibration, Labom have an in-line calibration method, whereby the instruments do not need to be removed from the process line.

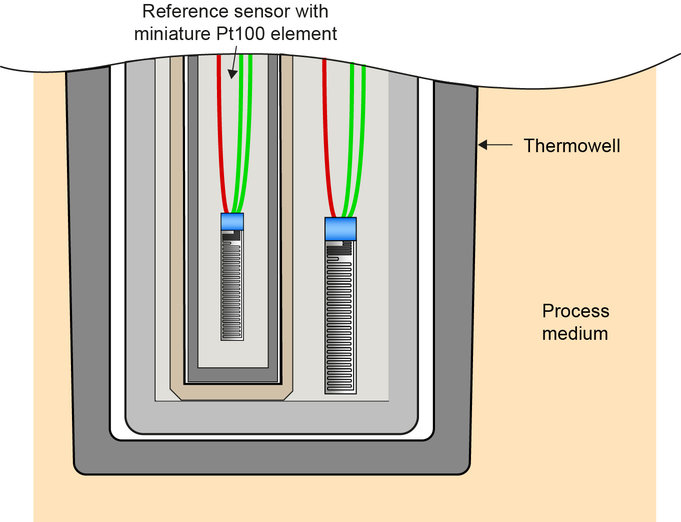

Labom’s temperature measurement instruments are designed in a way so that the comparison between the temperature sensor and a certified reference sensor can be performed in process. The certified reference sensor is inserted into a special calibration opening in the device. The two sensors are then in very close proximity to each other and are warmed by the process media in the same manner, thus giving an accurate reference to calibrate the temperature sensor against.

To read more about Labom’s In-Process calibration method click here. Read on to understand what components Labom’s in-line calibration solution consists of.

Labom’s In-Process Calibration Solution

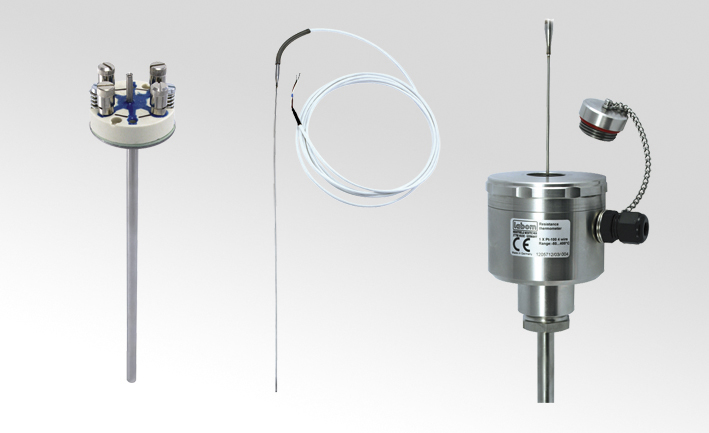

Labom’s PT100 Resistance Thermometer with measurement insert and reference sensor is the ideal solution for In-Process Instrument Calibration in both hygienic and standard applications.

The Electrical Resistance Thermometer

Resistance sensors work by measuring the electrical resistance of a material and how it changes as a function of temperature. This resistance change is measured and then converted into a standardised temperature reading.

Key Benefits

- Suited for operation in tanks, especially in hygienic applications

- All standard process connections are available, including connections suitable for Pharmaceutical, Food & Beverage and Biotechnology.

- Robust design – suitable for use in vast number of technological processes

- A variety of transmitters for head-mounting are available depending on application requirements

- Available with a reduced tip for fast response

Measuring Insert and Reference Sensor for In-Process Calibration

Labom measuring inserts are equipped with a test pipe where a calibrated reference sensor can be inserted to allow for In-Process calibration of temperature measurement instrumentation. This makes it possible to calibrate the installed resistance thermometer without disassembling the measuring insert.

Labom measuring inserts and reference sensors are extremely suitable for the Food & Beverage, Pharmaceutical, Chemical and Petrochemical and Machinery Construction Industries. They are available in various sizes and temperatures to meet specific application requirements.

An Application Example – Sterilisation with saturated vapor (SIP)

Any application with sufficiently constant process temperature to allow for the comparison of the two sensors is suited for Labom’s In-Process calibration method.

For example, sterilisation with saturated water vapor (SIP). Here, the measurement accuracy is only relevant at the sterilisation temperature and it is only necessary to ensure that the steam temperature is above the specified threshold.

So, for applications where accuracy requirements are not particularly stringent, In-Process calibration can be deployed and will deliver the following application benefits:

- Increased Productivity

- Reduced calibration costs

- No wasted engineering time

- Reduced safety & hygiene compromises

Is Labom’s In-Process calibration method the solution we need to lengthen the time interval between complete instrument calibration sessions?

What costs would this solution save in your application?

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.