Different Types of Pumps – Centrifugal Pumps

Centrifugal Pumps

Centrifugal pumps are perhaps the most common type of pump in operation today. With many different configurations available, centrifugal pumps are widely-used because of their design simplicity, high efficiency, wide range of capacity and head, smooth flow rate and ease of operation and maintenance.

Principle of Operation

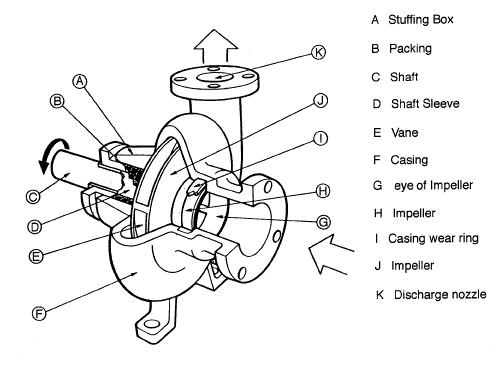

Centrifugal pumps use one or more impellers, which attach to and rotate with the pump shaft. This provides the energy that moves liquid through the pump and pressurizes the liquid to move it through the piping system. The pump therefore converts mechanical energy from a motor to energy of a moving fluid. A portion of the energy goes into kinetic energy of the fluid motion, and some goes into potential energy, represented by fluid pressure or by lifting the fluid, against gravity, to a higher altitude.

The transfer of energy from the mechanical rotation of the impeller to the motion and pressure of the fluid is usually described in terms of centifrugal force. The outlet pressure is a reflection of the pressure that applies the centripetal force.

A centrifugal pump works by the pump directing liquid in the system into the suction port of the pump and from there into the inlet of the impeller. The rotating impeller then moves the liquid along the spinning vanes, at the same time increasing the velocity energy of the liquid. The liquid then exits the impeller vanes and moves into the pump volute or diffuser casing, where the high velocity of the fluid is converted into high pressure through a diffusion process. The fluid is then guided into the discharge port of the pump and from there out into the system, or on to the next stage in the case of a multi-stage pump.

Centrifugal pumps are usually the preferred choice for lower viscosity (thin) liquids and high flow rates. They are typically used across many residential, commercial, industrial, and municipal applications.

Different Types of Centifrugal Pump

There are four main type classifications of centrifugal pump, with the chief distinction of each being the mechanism that drives the reciprocating diaphragm.

Mechanically Actuated

This type of pump has a reciprocating mechanical linkage that is directly attached to the diaphragm. The pump includes a gear set or other mechanical mechanism to convert the rotation of the motor into a reciprocating motion of the linkage that is attached to the diaphragm. Flow may be varied by varying the stroke length or pump speed.

Hydraulically Actuated

This type of operation employs an intermediate hydraulic fluid located on the non-product side of the diaphragm to flex the diaphragm. The hydraulic fluid is pressurized by a reciprocating plunger. Though it acts similar to a mechanically actuated diaphragm, the plunger isn’t attached to the diaphragm, but rather pressurizes the intermediate hydraulic fluid, which flexes the diaphragm. Flow is varied with this type of diaphragm pump by varying pump speed or by varying the amount of hydraulic fluid that is bypassed.

Solenoid

These pumps have an electric motor that alternately energizes and de-energizes a solenoid, creating an electro-magnetic force that reacts with a metal part on the diaphragm. This causes the diaphragm to flex. Flow is varied by varying the pump speed.

Air Operated Double Diaphragm Pumps (AODD)

This is a type of double acting pump. They have two diaphragms and two sets of check valves. The pump is driven by compressed air operating alternately on the non-product side of one diaphragm, and then the other. The air is delivered to the alternate sides of the diaphragm by means of a shuttle valve. Flow is varied by varying air pressure supplied to the pump.

Take a look at this YouTube video to see exactly how a Centrifugal Pump works:

Typical Applications

Diaphragm type centifrugal pumps are used in many applications across the commercial, industrial, municipal, and scientific fields. They are commonly used as metering pumps to pump precise volumes of liquid for treating water (e.g., drinking water, waste water, boiler water, swimming pool water, etc). They are used in process applications where very high pressures are required, where metering of fluids is needed, or where the sealless nature of this pump type is an important benefit. AODD pumps are often used to move liquids containing solids or where electricity is not available.

A common application of the multistage centrifugal pump would be in its deployment as a boiler feedwater pump. For example, a 350 MW unit would require two feedpumps in parallel. Each feedpump would be a multistage centrifugal pump producing 150 l/s at 21 MPa.

All energy transferred to the fluid is derived from the mechanical energy driving the impeller. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase). Multi-stage centrifugal pumps tend to be used for applications that require higher pressure or pressure head.

Diaphragm type pumps are generally deployed within the following ranges:

- Flow rate ranges between 20 to 750,000 lpm

- Total head (pressure) ranges between 0.3 to 215 Bar

- Horsepower ranges between 0.3 and 4,500 hp

There are a wide variety of materials of construction, ranging from various plastics and cast iron or stamped stainless steel for lighter duties - to bronzes, stainless steels, exotic alloys, and specialty plastics for more corrosive, abrasive, hygienic, or other difficult applications.

Primary Advantages of Centifrugal Pumps

- There are no drive seals, therefore the risk of leaks is completely eradicated. This means that hazardous liquids can be pumped without spillages. Eliminating the drive seals gets rid of leaks, friction loss, wear and noise and provides complete separation of fluid from the pump drive. This ensures that nearly 100% of the motor power is converted into pumping power.

- No heat transfer from the motor—the pump chamber is separated from the motor by an air gap; providing a thermal barrier.

- Complete separation from the process media means that liquid cannot seep into the motor from the pump.

- Reduced friction.

- Magnetic coupling can be broken if the load of the pump is too great. By the magnetic coupling 'breaking', it means the pump does not overload and get damaged.

Primary Disadvantages of Centifrugal Pumps

- Liquids containing ferrous particles are problematic when a magnetic drive pump is used. This is due to the particles collecting on the impeller magnet, and over time causing the pump to stop working.

- Some energy is lost in the coupling. This is primarily due to some magnetic resistance.

- If unexpectedly heavy loads occur, it may cause the coupling to slip.

Some typical problems that can be encountered by these pumps are identified below;

- Cavitation — this can occur when the net positive suction head of the system is too low for the selected pump.

- Excessive wear of the impeller — this condition can often be worsened by suspended solids.

- Corrosion inside the pump caused by the fluid properties.

- Surge or back surge in the line.

- Overheating of the pump due to low flow.

- Leakage of the media along the rotating shaft.

- Lack of prime—centrifugal pumps must be filled (with the fluid to be pumped) in order to operate.

Most centrifugal pumps are not self-priming. In other words, the pump casing must be filled with liquid before the pump is started, or the pump will not be able to function. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line.

So, that is an overview of Centrifugal Pumps. Do you have anything to add?

Any advantages or disadvantages in application? Or is there anything we didn't cover which you would like to know?

Either leave your comments below, click here to ask us a question, or give us a call on +44 (0) 8707 66 77 78.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.