How do different types of level measurement devices work?

This article gives an overview of how the common level measurement devices work, covering; radar level transmitters, guided radar transmitters, ultrasonic level transmitters and finally capacitance level transmitters.

Click here for more information on the technologies behind level measurement and the Time of Flight principle.

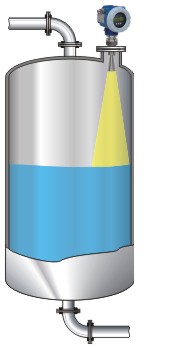

Radar level transmitters

How do radar level transmitters work?

Radar level transmitters work with high-frequency radar pulses which are emitted by an antenna and reflected from the product surface. The time of flight of the reflected radar pulse is directly proportionate to the distance traveled. If the tank geometry is known, the level can be calculated from this variable.

Advantages of radar level transmitters

- Very accurate - ±0.5 mm (0.02 inches)

- Installation at top

- Non-contact

- Accuracy independent of dielectric constant, density and conductivity

- No re-setup required when changing liquids

Things to take into account:

- Must take into account tank design

- Foam can be an issue

- Blocking distance

- Turbulent surfaces

- Minimum dielectric constant

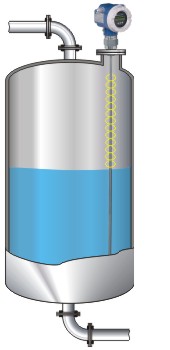

Guided Radar level transmitters

How do Guided Radar level transmitters work?

Guided Radar level transmitters work with high-frequency radar pulses which are guided along a probe. As the pluses impact the medium surface, the characteristic impedance changes and part of the emitted pulse is reflected. The time between pulse launching and receiving is measured and analysed by the instrument and constitutes a direct measure for the distance between the process connection and the product surface.

Advantages of Guided Radar level transmitters

- Very accurate - ±0.2 mm (0.04 inches)

- Works with some foam

- Installation at top

- Accuracy independent of dielectric constant, density and conductivity

- No re-setup required

Things to take into account:

- Must take into account tank design

- Heavy foam can be an issue

- Blocking Distance

- Turbulent surfaces

- Minimum dielectric constant

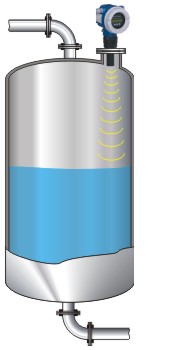

Ultrasonic level transmitters

How do Ultrasonic level transmitters work?

Ultrasonic measurement is based on the time-of-flight principle. A sensor emits ultrasonic pulses which the surface of the medium reflects and the sensor detects again. The required time of flight is a measure for the distance travelled in the empty part of the tank. This value is deducted from the overall height of the tank to yield the level.

Advantages of Ultrasonic level transmitters

- Non-contact (lowest cost)

- Installation at top

- Accuracy independent of density changes, dielectric or conductivity

- No calibration with medium required

Things to take into account:

- Minimum density required

- Foam is an issue

- Blocking Distance

- Turbulent surfaces

- Vapours/gas above the liquid

- Temperature difference between liquid and sensor

- No vacuum (10 psia), no high pressures (44 psia)

Capacitance level transmitters

How do Capacitance level transmitters work?

The principle of capacitive level measurement is based on the change in capacitance of the capacitor due to the change in the level formed by the probe and the container wall. When the probe is in the air, a low capacitance is measured. When the container is filled, the capacitance of the capacitor increases the more the probe is covered. A capacitance probe may be compared to an electric condenser. As the tank is filled, the probe capacity increases. This change is electrically analysed.

Advantages of Capacitance level transmitters

- Very cost effective

- Established principle

- Fast speed of response

- Interface measurement possible

- High temperatures and pressures possible

Things to take into account:

- Many versions

- Conductive/insulator

- Probe coating - chemical compatibility

- Ground reference tube

- Non-metallic

- Re-calibration with different media

- 10 pF minimum span

- Foam can be an issue

Other resources...

If you would still like to learn more about the principles or technolgoies behind level measurement, follow the links below:

Level measurement for hygienic applications

Resources for this article:

Material from experts in level measurement, Endress & Hauser, were utilised in compiling this article.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.