Catalytic converter for high quality Oil Free Air in Compressed Air Systems

There is an increasing demand for higher-quality compressed air in chemical, process and medical applications. Process air cleanliness creates different requirements depending upon the application: the more sensitive the application, the more demanding the requirements for air quality – especially where air comes into direct contact with products. Contamination from hydrocarbon-residues or airborne organic agents can strongly impair process safety and compromise the quality of end products. This is exactly the point where air-cleanliness becomes a critical control point for business success.

High Quality Oil Free Air

No single process or product will deliver high-quality compressed air, often referred to as ‘Oil Free Air’. Many air compressor manufacturers have different ranges of ‘oil-free’ or ‘oil-cooled’ systems, but these systems will invariably require primary or secondary downstream purification systems. The main source for oil in compressed air is the compressor: some of the lubricating oil from oil-lubricated machines always enters the compressed air. In order to prevent this, the installation of compressors with oil-free compression is often favoured. But in doing so, compressed air users may be lulling themselves into a false sense of security: the compression method prevents additional lubricating oil from entering the compressed air. However, this is by no means a guarantee that the compressed air is free from oil.

Typical Contaminants in Compressed Air Systems

Air compressors draw in huge amounts of atmospheric air, which continuously fills a compressed air system with contaminants that must be filtered and removed. The air passes through the compression stage, the after-cooling stage and then into some sort of storage device. All of these stages are sources of contamination for compressed air. There are typically 10 contaminants found in a compressed air system:

- Liquid Water

- Water Vapour

- Water Aerosols

- Oil

- Oil Vapour

- Oil Aerosols

- Atmospheric Dirt

- Microorganisms

- Rust

- Pipe-scale

Filtering contaminants in a compressed air application

Filters in a compressed air system will typically be a coarse and a fine filter set-up and it is believed that one filter is a particulate filter and the other is an oil-removal filter. In reality, these 2 filters are coalescing filters and combined to remove varying levels of contaminants, such as Water Aerosols, Oil Aerosols, Atmospheric Dirt, Microorganisms, Rust and Pipescale. To remove oil from a compressed system, you need to install some form of catalytic converter.

The BEKOKAT catalytic converter for Oil Free Air

The BEKOKAT® sets new standards with its trendsetting technology: with a residual oil content down to a barely measurable 0.001mg/m3 - and an absolute absence of biological contaminants – air cleanliness is taken to a new level.

How does the BEKOKAT Catalytic Converter work?

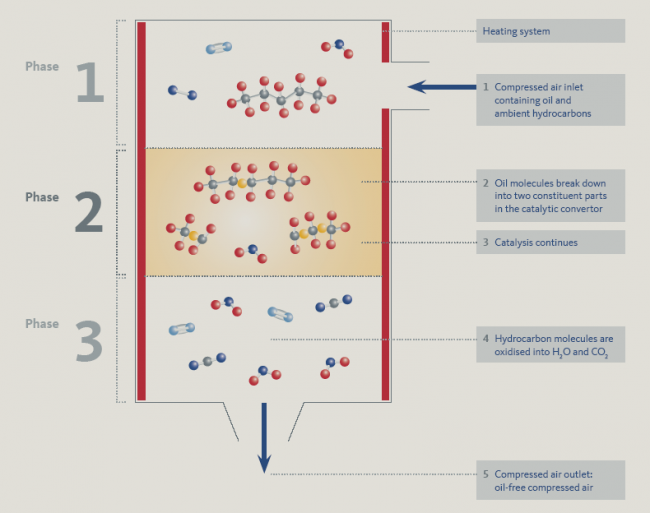

The BEKOKAT catalytic converter works by converting gases and/or hydrocarbons by the process of oxidation, producing less harmful gases such as Carbon Dioxide and Water vapour. This operation is not dependant on the temperature and humidity of the compressed air to be treated but will continuously supply air with a residual oil content of less than 0.003mg/m3. The basic formula for this conversion is CnH2n+2 +O2 = H2O + CO2.

Four steps to Oil Free Air:

1. Oil-containing cimpressed air enters the system 2. Oil molecules are broken down into 2 parts at the catyltic conveter – catalysis is continued 3. Oil molecules are oxidised down to H2O + CO2. 4. Oil-free compressed air is produced  The BEKOKAT is also ideally suitable for the retrofitting of existing compressor stations. In this manner, a compressor station with existing oil-lubricated compressors can easily be transformed into an oil-free compressed-air provision system without the need of expensive investments for new oil-free compressors. BEKOKAT systems are not only highly effective, but also very environmentally friendly.

The BEKOKAT is also ideally suitable for the retrofitting of existing compressor stations. In this manner, a compressor station with existing oil-lubricated compressors can easily be transformed into an oil-free compressed-air provision system without the need of expensive investments for new oil-free compressors. BEKOKAT systems are not only highly effective, but also very environmentally friendly.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.