Self-Cleaning pumping system for reducing life time costs in wastewater pumping applications

The best wastewater pumps in the world will still fail and cost end-user’s significantly if they are installed into poor pumping systems.

There are many factors which can influence a sewage pump to block or fail, so attention to the fundamentals of sewage pumping station design are essential. An essential design element when considering reduced life-time costs are ‘self-cleaning pumping systems’. Self-cleaning pumps can directly reduce maintenance costs significantly, whilst contributing to reduced life-time costs and TOTEX objectives.

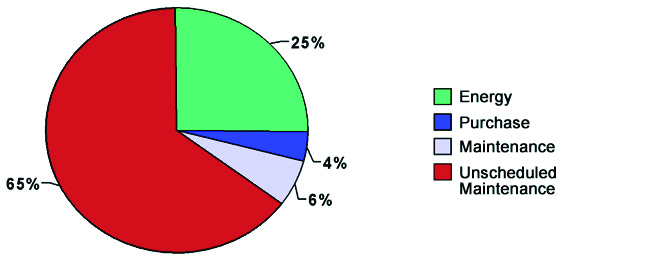

The cost of unscheduled pump maintenance

The cost to unblocking sewage pumps is one of the largest contributory factors to unscheduled pump maintenance today. The pie chart illustrates how this impacts on the whole life cost when small sewage pumps block once a week. Unscheduled maintenance surpasses any arguments about energy saving quite significantly.

The physical cost of pulling rags out of sewage pumps in the UK is unknown but is estimated to exceed £100 million per year. The energy costs associated with blocked pumping systems is significant; there is serious loss of energy when a sewage pump is not free flowing plus there are all the vehicle emissions associated with vans, cranes or tankers frequently visiting sites reactively to lift and unblock equipment.

There is little point in installing energy-efficient wastewater pumps, when those energy savings are offset with high energy consumption associated with on-going maintenance and repair.

Reducing whole lifetime costs and achieving TOTEX objectives

The Water Industry regulator is chasing for a TOTEX approach or ‘best whole life cost’ solution for installed assets. Only improved system engineering, approved signature solutions or new regulated standards for design can achieve this, engineers need to raise the bar here.

Hidrostal believe they can make a valuable contribution here by a wider adoption of the self-cleaning pumping station principles.

Self-Cleaning Pumps

Why is Self-Cleaning Important

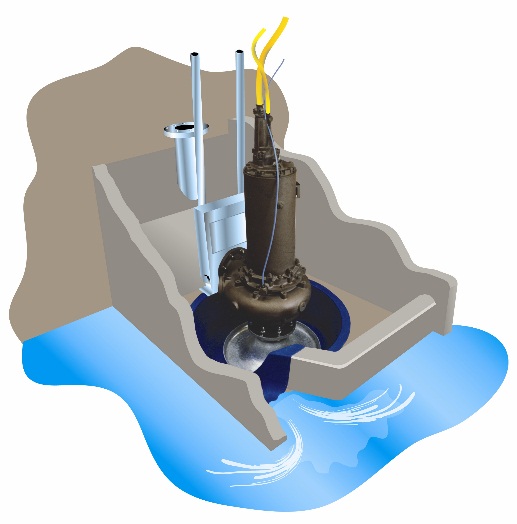

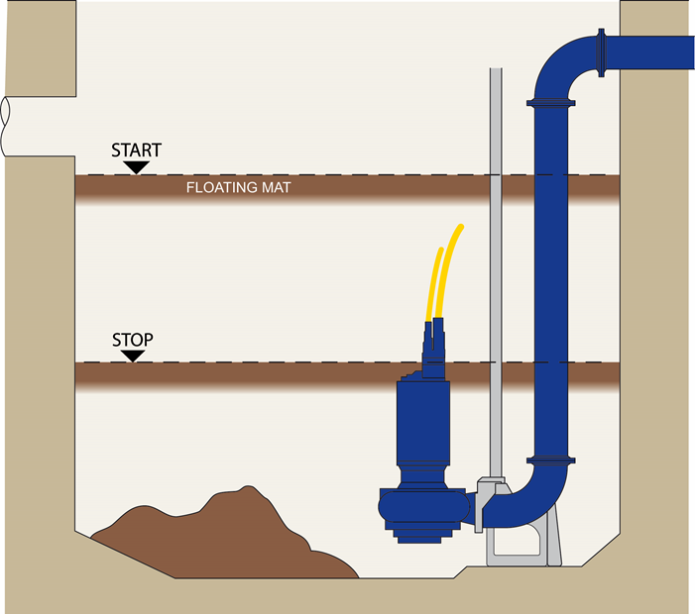

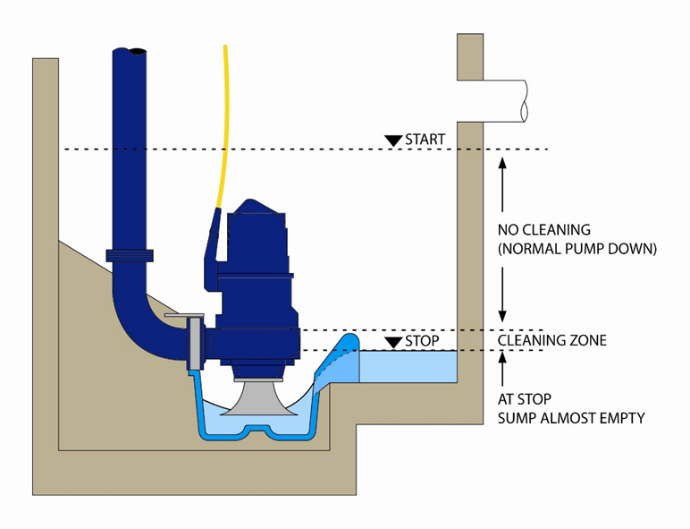

Pumping sewage should be about system solutions, not isolated products. That is why Hidrostal have a designed the Prerostal System; a Hidrostal sewage pump within a prerotation, self-cleaning basin.

Prerostal pumping systems utilise clever but simple hydraulic principles to aid the removal of virtually all floating, suspended and settled solids in each pump down cycle. This technology is appropriate, stable and simple for waste water pumping and can deliver a 20 – 40 year problem free asset life. The Prerostal pumping systems are now widely accepted and have proven results in real-life applications across the UK.

Watch a product demonstration of the Self-Cleaning Pumping System

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.