How different types of Positive Displacement Pumps work & their typical applications

How different types of Positive Displacement Pumps work

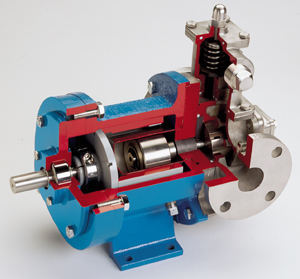

The term positive displacement refers to the way in which these pumps pressurize and move fluid.

Positive displacement pumps squeeze fluid by decreasing the volume that contains it. One type of positive displacement pump is a piston pump: every stroke pushes along a certain amount of fluid. An example of a rotary displacement pump is a screw pump, which uses two parallel, overlapping screws to push along a certain volume with each revolution.

Applications for Positive Displacement Pumps

Although positive displacement pumps have higher maintenance requirements than other types, they are inherently better suited for certain applications. These applications include the following:

- High-Pressure/Low-Flow Applications. Positive displacement pumps are usually more effective in generating high pressures in low-flow applications. Although centrifugal pumps can be designed to generate high pressures—usually through the use of multiple stages—these special pumps tend to be comparatively expensive.

- High-Fluid-Viscosity Applications. Positive displacement pumps are more effective than centrifugal pumps in moving viscous fluids. By directly pressurizing the fluids, positive displacement pumps lose less energy to the high shear stresses that are inherent in viscous fluids.

- Accurately Controlled Flow Applications. Since each stroke or revolution generates a certain amount of flow, positive displacement pumps are typically used in applications requiring precise flow control. By controlling the number of pump cycles, positive displacement pumps are well suited for metered-flow applications.

Advantages of Positive Displacement Pumps

In addition, many positive displacement pumps have certain unique characteristics that make them attractive. For example, positive displacement pumps are usually self-priming and can operate with entrained gases in the suction line. This feature allows system designers to place these pumps above the fluid level, which can simplify the system layout. Centrifugal pumps often require special system equipment to remove gases and prime the impeller. Although some centrifugal pumps are designed to be self-priming, they are also expensive, less reliable, and less efficient— and gas must still be removed.

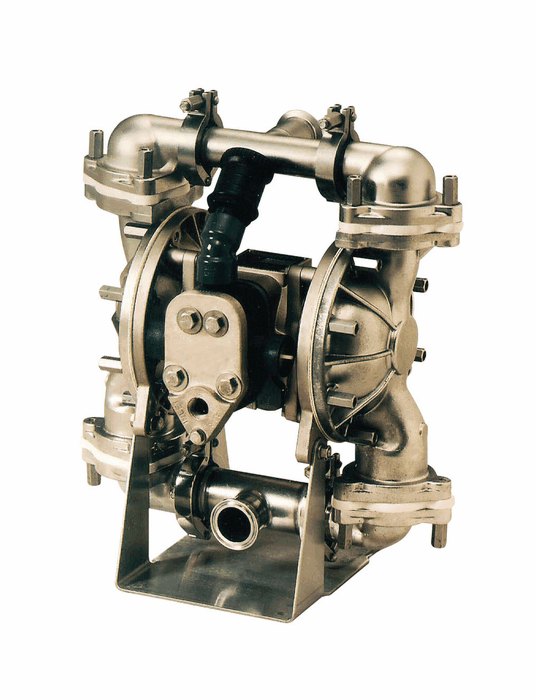

Certain positive displacement pumps—such as diaphragm and peristaltic types—do not require seals and thus do not leak. In systems that handle corrosive or hazardous fluids, eliminating the need for seal maintenance can yield substantial cost savings.

Positive Displacement Pumps and Pressure Relief Valves

Positive displacement pumps are usually installed with pressure relief valves. In fact, in many of these pumps, relief valves are internal to the pump. This protection is needed because the pumps push fluid into the discharge line irrespective of backpressure. Consequently, if the system flow becomes completely obstructed downstream of the pump, fluid pressure builds until the motor torque reaches an overload condition or until the piping or other equipment ruptures. Although relief valves are designed to protect against such damage, they require periodic testing and maintenance. A relief valve that fails to operate properly can cause costly system damage.

For more information on Positive Displacement Pumps visit the British Pump Manufacturers Association.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.