ASV Stübbe’s Magnetic Coupled Pump saves on Leakages and Maintenance costs

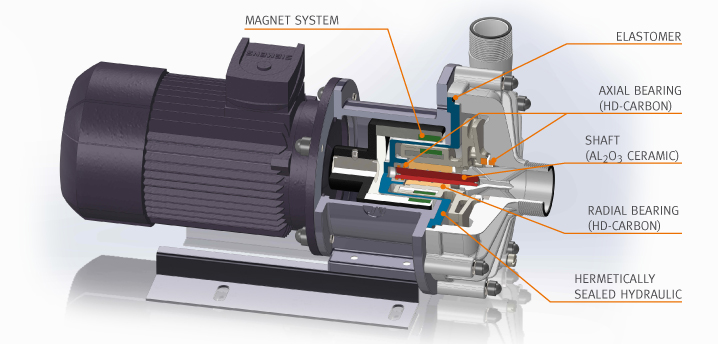

The magnetic coupled pump SHM from ASV Stübbe - with its powerful magnet system, special bearing combination and hermetically sealed hydraulic - ensures dangerous leakages and costly repairs are a thing of the past, even during dry-running.

How does the magnetic coupled pump SHM? work?

The magnetic coupled pump SHM ensures a reliable power transmission due to a powerful and efficient magnet system. During the process, the engine power is being transmitted efficiently to the pumps impeller without direct contact. Due to the special bearing combination, the slide bearings (Al2O3 and HD-Carbon) do not need any lubrication to keep bearing friction - and the resulting frictional heat - as low as possible. This results in a high reliability to remain undamaged during the dry-running process.

The hermetically sealed hydraulic eliminates flaws of mechanical sealed centrifugal pumps and prevents leakage caused by worn or damaged mechanical seals. This guarantees absolute leak tightness and ensures a clean and flexible work process. It makes the SHM magnetic coupled pump especially suitable for dangerous media, where even the tiniest leakage means a high security risk. Cost-intensive maintenance of mechanical seals, and the resulting unavailability of the system, are therefore effectively being avoided.

The application of ASV Stübbe’s magnetic coupled pump at CG Chemikalien

CG Chemikalien in Laatzen, near Hanover, uses ASV Stübbe's SHM magnet coupled centrifugal pumps to produce caustic soda lye, sulphuric acid, phosphoric acid, nitric acid, acetic acid and formic acid in concentrations of up to 99 percent. The company's client base includes well-known companies from the automotive, steel, pharmaceutical and cosmetics industries, with a portfolio ranging from window cleaning products, and active ingredients, to foods and animal feeds.

They have used ASV Stübbe's product solutions for over 20 years, as they're perfectly tailored for use with acids and alkalies. In their Laatzen facility the magnetic coupled pump type SHM is installed to specially designed transport trolleys to enable the filling of the tanks. In the process, the pumps are exposed to highly aggressive chemicals and have to function time and time again during dry-running; a process, that demands absolutely everything of material and machine.

“When it comes to pumps CG Chemikalien is a rough working company,” says plant manager Michael Schäfer. “If anybody pushes those pumps to their limits, it's definitely our company. The SHM pumps are being used for the mobile pumping of various media like hydrochloric acid, sulphuric acid, formic acid and nitric acid. We're currently using ten pumps in our facility and can definitely say and assure that no other pump can cope with the strains of these tough and extremely demanding working conditions.”

Technical specifications

- Head: up to 27 meters.

- Flow rate: 65m²/h.

- Drive capacity: 0,18 kW up to 7,50 kW.

- Materials:? Hydraulic PP, PVDF? Seals EPDM, FPM, FFKM ?Sliding bearing (rotary/static): HD-Carbon/Al2O3, SSiC/SSiC, HD-Carbon/SSiC.

Product benefits

- Safe dry run capability (HD-Carbon/Al2O3).

- Mechanical separation of pump and engine due to hermetically sealed hydraulic part.

- Compact design, mobility and flexible installation.

- No mechanical sealing – 100% leak tightness, low maintenance.

- Good availability due to modular design and six different sizes. Visit ASV Stübbe for more information.

Visit ASV Stübbe for more information.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.