What is distributed I/O and what are the benefits?

With ever larger systems, and increasingly complex processes, ensuring a centralised system for measuring and controlling all aspects of the plant is vital. Pooling data, which often originates from several different sites, into one single location is at best a challenge and at worst a logistical nightmare. Could distributed I/O be the answer? PIF investigates.

What is distributed I/O?

Distributed I/O systems include small field devices with a wide range of I/O options. These can include digital and analogue channels, temperature measurements, and counter inputs. These modular devices provide a flexibility distinctly lacking in traditional devices, like Programmable Logic Controllers (PLCs), that require a high density channel count and long cable runs.

What are the benefits of distributed I/O?

The beauty of the distributed approach is that it allows for short cable runs for signals (because measuring devices are closer to the sensors). Direct connection of sensors also eradicates signal conditioning, with the added benefit of standard signal inputs for specialised sensors.

According to Amplicon,

Utilising reliable and conventional communication buses such as Ethernet and RS485 with protocols such as Modbus/TCP, Modbus/RTU, Profibus, and even ASCII, modules can be integrated into existing networks and systems, giving a low cost, flexible upgrade path.

What types of distributed I/O systems are available?

As you can imagine, there are countless distributed I/O systems available on the market today. We've chosen three standout examples to demonstrate what's out there currently.

Murrelektronik's Cube67

Murrelektronik's Cube67 is a modular, distributed I/O system that uniquely combines IP20 and IP67 protection (plug-connected, robust and fully encapsulated). The I/O layer spreads radially, starting at the bus coupler, throughout the application. The hybrid system cable connections – for power supply and communication between individual components – are rational and clear.

I/O modules are available for digital, analog, and serial signals; temperature sensing; counters; valve clusters; and drive or operating-panel attachment. It also offers end-to-end, channel-specific debugging all the way down to the sensor/actuator. Digital channels are freely programmable, meaning that the M8 or M12 plug position, or the signal terminal for example, can be used as an input or output (multifunctional).

SIMATIC ET 200

Siemens' SIMATIC ET 200 systems are multifunctional, modular and precisely scalable systems for distributed automation. Their distributed I/O systems are ideal in control cabinets, at the machine, and in hazardous explosive areas. All products within their range can be integrated into existing automation systems via PROFIBUS or PROFINET.

With multichannel modules and simple wiring, the ET 200MP is ideal for centralized cabinet installation. For the distributed I/O in the cabinet, the ET 200SP scores highly thanks to its compact design. While the light and easy to install, ET 200AL, is the perfect solution for applications outside the cabinet (it also meets the quality standards of IP65/67).

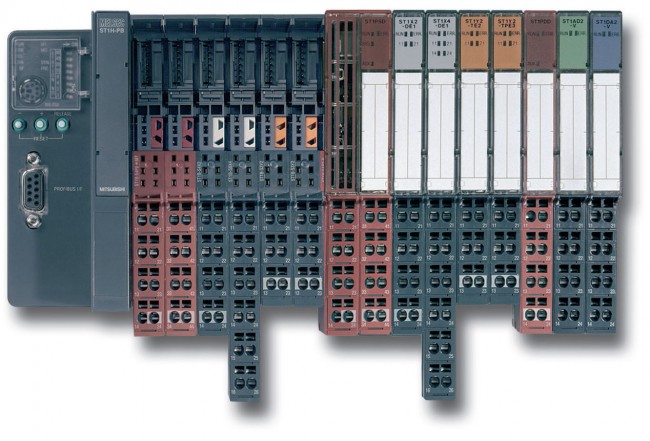

Mitsubishi Electric's ST Series

Mitsubishi Electric's ST Series is a distributed I/O system that operates as a slave device for either CC-Link or Profibus device level networks. This modular system features a head unit, power supply and compact I/O that snaps quickly together on DIN rail to form a remote system or node. It enables builders to easily configure nodes that are flexible and provide long term serviceability while best meeting machine requirements.

Plant personnel will appreciate the expansion capabilities, as well as the ability to quickly service and replace I/O without impacting production. Ideal for machine builders and manufacturing facilities seeking moderate I/O concentrations.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.