Sliding gate valves retrofitted in power generation application reduces fuel consumption

The application benefits of sliding gate control valves are huge. Sliding gate control valves have excellent control characteristics, extremely short strokes, low leakage rates, long service lives – the list goes on. In a power generation applications, the innovative design characteristics of sliding gate control valves offer application benefits such as reduced fuel consumption, maximum efficiency and safer, more reliable control.

By installing sliding gate control valves in a power generation application at Munich airport, the following application benefits were delivered:

- By installing sliding gate valves the fuel consumed by the power generators was reduced.

- The combination of sliding gate valves with digital positioners improved operating performance

- Extremely short stroke of sliding gate valves means short opening & closing times and maximum control performance

- The innovative design based on 2 slotted discs means high control with low leakage rates & long service life

- Sliding gate control valves offer maximum efficiency from application and Increased energy yield

- Sliding gate control valves allow for remote control of the application and a safer, more reliable control option.

Read the application story below to learn exactly how Schubert & Salzer’s Sliding Gate Control Valves delivered these application benefits to Munich Airport.

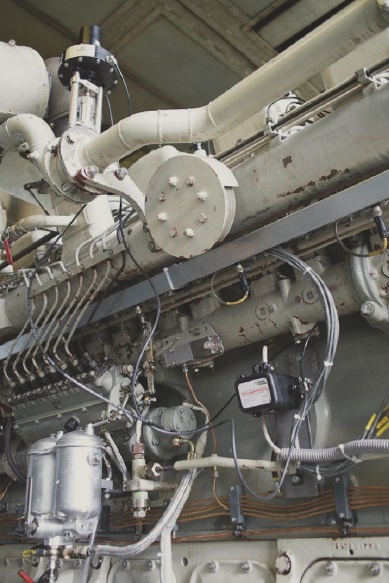

A power generation application

Munich’s main airport generates over 50% of its power itself, about 122,000 MWh p.a., using 9 power generators. The 7 duel fuel engines and 2 spark ignition gas engines used in the power generation application are combined power, heating & cooling machines. The released heat is also being used for the central-heating during the winter period, whereas in summertime the air conditioning benefits from the lost heat due to the employment of absorption cooling machines

During the warming up phase, which lasts for a few minutes, duel fuel engines operate solely on diesel fuel. After this, a natural gas / air mixture is fed into the engine which is ignited by the diesel fuel element, its proportion now reduced to 10%. As a result, the power generators can be operated more efficiently.

Sliding gate valves with digital positioners were installed on the first two power generators to regulate the natural gas / air mixture.

Sliding gate control valves for power generation

By installing sliding gate valves in the power generation application, the power generators can be operated more efficiently. Sliding gate control valves have been installed on the first 2 power generators to regulate the natural gas/air mixture.

Sliding gate valves for precise control

The maximum stroke of a sliding gate valve is a mere 8 mm. This facilitates extremely short opening and closing times (optionally up to < 10 msec) for the complete stroke. Through a resolution of 0.1% of the stroke position, a very dynamic response is reached which not only improves the control quality but forms the basis for control circuits with very short reaction times. This proves to be the defining key to highly efficient and precise control operations.

Sliding gate valves for low leakage & long service life

With its special design based on two slotted discs sliding against each other and forming a seal, sliding gate valves are the only valves that combine high control accuracy with the lowest leakage rate. Also the throttling element - the slotted discs that slide against each other - suffers scarcely any wear so that long service lives can also be achieved under extreme conditions, an inherent feature of the system design.

Sliding gate valves for maximum efficiency

As a result of retrofitting the sliding gate valves with digital positioners, the engines in the generating plant at the airport can be operated directly from the control room at maximum efficiency. The exhaust gas temperatures are measured continuously to optimise the combustion control of the natural gas / diesel / air mixture and the sliding gate valves accurately adjust the quantity of natural gas needed. Thus, the high control precision of the sliding gate valves minimises the consumption of natural gas as well as the ammonia used in cleaning the exhaust gas.

Remote controlled sliding gate valves

Beforehand, the natural gas supply was controlled by butterfly valves with a mechanical stop. These could only be adjusted in the engine room. Thanks to the sliding gate valves with positioners, the amount of gas / exhaust temperature of the power generators can be precisely controlled and corrected if necessary remotely from the control centre.

Sliding gate control valves offer safer & reliable control

When the duel fuel engines operate on diesel only, the use of the digital positioners guarantee a high degree of operational reliability. It is essential in this operating state that no natural gas is being supplied. The positioner software enables the triggering of a system alarm when there is an attempt to interfere with the local valve control. Therefore, if there is any unauthorized manual interference at the newly installed gas flow control valves, an alarm is set off immediately in the control room.

Sliding gate valves deliver application benefits such as these across the whole Process Industry.

Link: Versatile control valve for many applications: cryogenic, shipbuilding, chemical and steam

To find about more about Schubert & Salzer’s sliding gate control valves, contact Schubert & Salzer directly or ask Schubert & Salzer experts a question in the PIF Solution Centre.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.