Manual pressure regulating valves for conveyor belt alignment and tensioning

The R27 manual regulators from Norgren have a robust design and mechanical closed loop control to provide instrument precision regulation for all environments. This article explains how precision closed loop regulator valves can be installed on either side of a conveyor belt to control belt tensioning.

The Application challenge: Adjustable belt alignment

Production conveyor belts can often experience excessive wear due to operational misalignments. When a misalignment occurs, it can cause possible lost production time and require an urgent maintenance repair. It can also contribute to jamming of the product on the conveyor belt and even cause product or packaging damage.

Intermittent misalignment of belt & excessive wear

In a recent application at a well known biscuit manufacturing company, the boxes of product were being deposited on to the conveyor belt from the side, leading to a progressive misalignment of the belt and excessively uneven belt wear. It was observed that the extent of the distortion was directly related to the weight of the product and so for large cartons this had the potential to be quite destructive to the package handling system, if not properly controlled. The important challenge was that the belt misalignment was only occurring intermittently when a heavier load was deposited onto the belt.

The Solution: R27 regulator valves to control belt tensioning

The solution to this particular application problem was to use a pair of precision closed loop regulator valves on either side of the conveyor belt to control belt tensioning. The Watson Smith R27 air piloted regulator valve was able to successfully deliver this control. This valve is an air piloted manual regulator with an internal mechanical closed loop control, allowing highly accurate positioning across a wide variety of environments.

Regulated pressure control using lever and knob operated valves

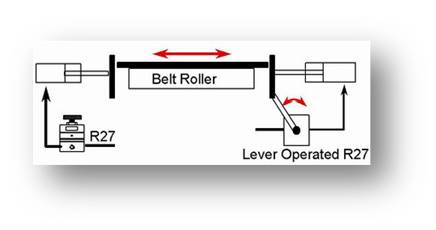

On one side of the conveyor system, the R27 regulating valve was configured with a knob control so that the operator could adjust the belt tension and position depending on the product load.

On the other side of the belt, a lever operated R27 valve was deployed so as to operate as a pneumatic position convertor. In this instance, the lever was mechanically connected to the belt movement and so as the lever moved with the distortion, it regulated pressure as necessary to move the piston attached to the belt back in position.

The outcome was that the R27 belt-tensioning control completely eliminated conveyor belt misalignment and so the R27 valves have now become a standard fit into many belt-tensioning systems.

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.