Invasive temperature measurement Vs. Non-Invasive temperature measurement techniques

Temperature measurement equipment is used throughout the Process Industry, in hygienic, pharmaceutical, biotech and general process applications. This article discusses LABOM's temperature measurement devices and their suitability to different process applications.

This tutorial article is part one of a two-part series of articles discussing invasive and non-invasive temperature measurement. This article explains the different technologies behind invasive and non-invasive temperature measurement methodologies, as well as highlighting the basic advantages and disadvantages of each method. The second article discusses under which process conditions non-invasive temperature measurement is more suitable.

Invasive Temperature Measurement

The most common type of temperature measurement uses a temperature-sensitive sensor, often a Pt100 element, which is inserted into the process. Use of such devices is referred to as ‘invasive measurement’ as it invades the process media. For the pharmaceutical or food & beverage industry, clamp-on or aseptic screw connections are used and the temperature measurement device is designed in such a way that it can be easily removed for the required calibration without interrupting the process. For example, a replacement measurement probe is used.

This temperature measurement technique is known as ‘Invasive temperature measurement’ and is a very well-tested and stable temperature measurement technique.

Disadvantages of invasive temperature measurement:

In applications with small pipe diameters (common in pharmaceutical applications), an invasive sensor tip reaching into the process area can be a significant obstacle to flow. Furthermore, the interfaces between the process connection and the system and between the measuring device and the process connection also present a significant hygiene risk. Finally, invasive temperature measurement techniques can be a more costly approach as maintenance requirements can be higher, for example, elastomer seals need to be replaced regularly.

Non-Invasive Temperature Measurement

Non-invasive temperature measurement is also known as ‘pipe surface measurement’ and has now become a popular temperature measurement technique in pharmaceutical or hygienic applications. Measurement of the pipe surface avoids any interference with the process, thus precluding hygiene risks caused by measurement. This temperature measurement technique can now be used with small pipe diameters, is quick and easy to install and can be integrated into existing systems very easily.

Non-Invasive measurement technology 1:

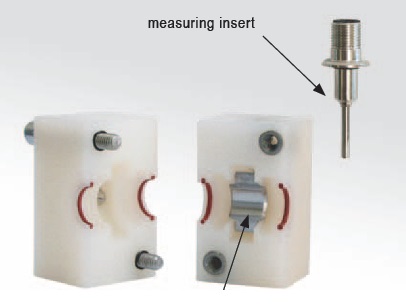

A contact element establishes the connection to the pipe, a measurement probe is then inserted into the invasive element.

Advantage: The same type of measurement probe used in invasive methods can be used, thus the calibration requirements and procedures are the same.

Disadvantage: This version does not always fulfil the requirements for response time and measurement accuracy.

Non-Invasive measurement technology 2:

A measurement probe has direct contact with the pipe surface.

Advantage: This technique significantly reduces the heat capacity of the measuring device and thus the response time. The measurement accuracy is also very high.

Disadvantage: The achievable accuracy depends significantly on process conditions and installation errors can have an impact on the measurement accuracy.

Applications for non-invasive temperature measurement?

Despite the obvious advantages,non-invasive measurement techniques are often overlooked due to the lack of practical application of such technologies. The second part of this tutorial will explain under what application conditions, the pipe surface measurement technology will deliver the most application benefits.

What is your preferred temperature measurement technology?

Do you have any experience with pipe surface measurement?

If you would like to ask any technical questions about different temperature measurement technologies, ask our LABOM experts in the Solution Centre. If you have any comments or feedback, please leave them below!

Get the latest process industry news

Interested in receiving even more industry-leading news from Process Industry Forum delivered directly to your inbox? Then sign up to our free newsletter. Bringing you the latest news, trends, innovations and opinion from across the process industry, our exclusive newsletter gives you all the industry insights of the moment in one, easy-to-digest bulletin. Stay ahead of the competition with regular process industry news instalments from PIF.